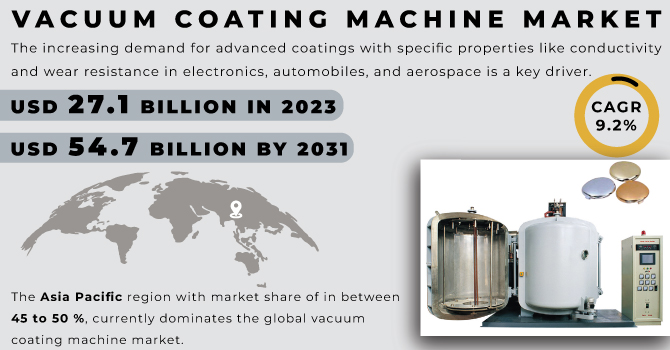

The Vacuum Coating Machine Market Size was valued at USD 27.1billion in 2023 and is expected to reach USD 54.7 billion by 2031 and grow at a CAGR of 9.2 % over the forecast period 2024-2031.

The increasing demand for advanced coatings with specific properties like conductivity and wear resistance in electronics, automobiles, and aerospace is a key driver. This translates to a need for precise and complex thin film deposition, a task well-suited for these machines. For instance, in the electronics industry, vacuum coaters are crucial for depositing thin films of copper for improved circuit performance. The growing focus on automation and efficiency in manufacturing creates a demand for advanced vacuum coating machines with these capabilities. For example, the automotive industry is embracing automation for applying wear-resistant coatings on car parts. Furthermore, environmental regulations are pushing for eco-friendly coating processes, opening up opportunities for retraining workers on new techniques like reactive sputtering.

To get more information on Vacuum Coating Machine Market - Request Free Sample Report

KEY DRIVERS:

Rising Focus on Automation and Efficiency

Increasing Demand for Advanced Coatings

Advancements in various industries like electronics, automobiles, and aerospace require deposition of thin films with superior properties like high conductivity, wear resistance, and corrosion protection. Vacuum coating machines are instrumental in achieving these precise and complex coatings.

Example, In the electronics industry, the demand for evermore miniaturized and efficient circuits necessitates the use of advanced vacuum coating equipment for depositing thin films of materials like copper and titanium nitride for improved conductivity and durability.

RESTRAINTS:

The initial expense for purchasing, installing, and setting up these machines might be significant. This can be a barrier to entry for small businesses or those exploring novel Product Types.

Lack of Skilled Workforce

Operating and maintaining vacuum coating machines requires specialized knowledge and technical skills. A shortage of qualified personnel can hinder the adoption and efficient use of these machines.

Example, troubleshooting complex coating issues or optimizing deposition processes for new materials might require technicians with a deep understanding of vacuum science, thin-film deposition techniques, and specific equipment functionalities. Finding such skilled labor can be challenging for companies, especially in regions with limited training programs in these areas.

OPPORTUNITIES:

Integration of Advanced Technologies provides various opportunities.

The incorporation of technologies like artificial intelligence (AI) and the Internet of Things (IoT) into vacuum coating machines is transforming the industry. Upskilling the workforce in these areas will be crucial for operating and maintaining these advanced systems.

Example, Vacuum coating equipment manufacturers are developing AI-powered controls that can optimize process parameters in real-time. Retraining programs can help workers understand and leverage these intelligent systems for improved productivity and quality control.

CHALLENGES:

Stringent environmental regulations pose challenges.

The cost of raw materials used in the vacuum coating process, like target materials and sputtering gases, can be volatile.

While environmental regulations are a driver for advancements in eco-friendly coating techniques, complying with these regulations can also present challenges for manufacturers. Strict emission limits or restrictions on certain materials might necessitate investing in additional equipment or adopting new processes that require retraining of the workforce.

Both Russia and Ukraine are significant players in the metal and rare earth element industries, which are crucial raw materials for target deposition in vacuum coating. The war has caused shortages and price hikes for these materials, impacting production costs and lead times for machines. Sanctions imposed on Russia have restricted the export of high-tech goods, including some vacuum coating equipment. This has limited sales opportunities for manufacturers targeting the Russian market, impacting overall market growth. Also,The war has driven up global energy prices, including natural gas, a critical component for powering vacuum coating machines. This rise in operational costs can lead manufacturers to postpone equipment purchases or reduce production capacity.

For Eg. The aerospace sector is the most impacted due to its reliance on advanced coatings for aircraft parts. With sanctions on Russia, a major aerospace player, and the disruption of global supply chains, there's a slowdown in production and a decreased demand for specialized vacuum coating equipment used in this sector.

Economic slowdowns can lead to disruptions in the supply chain for raw materials and components needed for vacuum coating machines. This can cause delays in production and increase costs. Companies tighten their budgets during economic downturns, leading to decreased investment in new equipment, including vacuum coating machines. This decline in demand directly affects sales and profit margins for manufacturers. For Eg. Durable Goods Manufacturing, his sector, encompassing industries like automotive, construction, and appliances, heavily relies on vacuum coating for decorative finishes, corrosion resistance, and improved functionality. During an economic slowdown, demand for these durable goods weakens, leading to a significant decline in vacuum coating machine sales in this sector. Stainless steel appliances often utilize vacuum coatings for a polished look and corrosion resistance. In an economic slowdown, consumers might opt for less expensive appliances, reducing the demand for vacuum-coated finishes. however the increasing demand for consumer electronics and other coated products in developing economies like China and India is expected to fuel market growth.

By Process

Physical Vapor Deposition (PVD)

Chemical Vapor Deposition (CVD)

The vacuum coating equipment market is segmented by process, physical vapor deposition (PVD) and chemical vapor deposition (CVD). The physical vapor deposition (PVD) category accounted for the majority of revenue growth in the vacuum coating equipment market in 2021. Because of its low initial cost compared to other vacuum coating technologies, as well as its advanced plasma coating-based deposition technology, it provides various advantages, including improved hardness, robust wear protection, oxidation resistance, and low friction values.

By Product Type

The vacuum coating machines market is segmented by product type, which includes vacuum evaporation coating machines, vacuum sputtering coating machines, chemical vapor deposition (CVD), coating machines, and others. The chemical vapor deposition (CVD) segment dominated the market in 2021. Because of its capacity to deposit a coating onto a substrate in several directions, it is quickly becoming the most popular and widely used vacuum coating technology. This procedure, generally carried out in a vacuum, produces high-performance coatings.

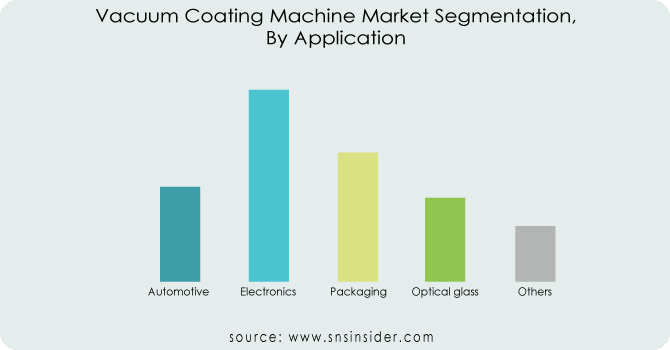

By Application

Based on the Application, the electronics segment held the dominant position in the Vacuum Coating Machine Marketwith the market Share of upto 40%. this growth is mostly attributable to ongoing advancements in areas like digitalization, 5G, and IoT. The demand for microelectronic devices and seed layers for plating continues to drive market growth. The Vacuum Coating Machine Marketis diversifying with the packaging segment experiencing significant growth alongside the established electronics sector. This trend highlights the expanding role of vacuum coating technology across various industries.

Need any customization research on Vacuum Coating Machine Market - Enquiry Now

The Asia Pacific region with market share of in between 45 to 50 %, currently dominates the global vacuum coating machine market. This dominance is driven by factors like rapid economic growth and a surge in demand for consumer electronics also, the growing demand for barrier films and functional packaging in the Asia Pacific food and beverage industry is driving the market for vacuum coating machines in this segment. Many governments in the Asia Pacific region are actively promoting technological advancements and domestic manufacturing of vacuum coating equipment.

North America retains a significant share with its focus on advanced technology and established players. also, Strong presence of established vacuum coating machine manufacturers like Veeco Instruments and Kurt J Lesker Company. High focus on technological innovation and advanced applications. and Stringent regulations driving demand for high-performance coatings. for eg. In April 2024, A leading North American manufacturer, Veeco Instruments Inc., announced a new generation of sputtering equipment specifically designed for the growing microelectronics market. overall Rising demand for lightweight materials and anti-corrosion coatings in the North American automotive industry is expected to create new opportunities for vacuum coating machine manufacturers.

REGIONAL COVERAGE:

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of the Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

The major key players are Applied Materials, ULVAC, Lam Research, Buhler, Optorun, Aixtron SE, Evatec, Shincron, Von Ardenne, IHI and Other Players

Lam Research-Company Financial Analysis

In April 2024, Veeco Instruments Inc. Launched a new generation of sputtering equipment designed specifically for the growing microelectronics market. this development caters to the increasing demand for miniaturized and high-performance electronic components.

In May 2024, The Chinese government announced a new investment plan to boost domestic production of advanced vacuum coating equipment. this initiative aims to reduce reliance on imports and strengthen China's position in the high-tech manufacturing sector.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 27.1 Billion |

| Market Size by 2031 | US$ 54.7 Billion |

| CAGR | CAGR 9.2% From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Application (Transparent Electrical Conductors, Optical Films, Packaging, Hard and Wear-Resistant Coatings, Others) • by Process (Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), Others), • by Types (Vacuum Evaporation Coating Machine, Vacuum Sputtering Coating Machine, Chemical Vapor Deposition (CVD) Coating Machine, Others), by Industry Vertical (Electronics, Automotive, Power, Healthcare, Others) |

| Regional Analysis/Coverage | North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), The Middle East & Africa (Israel, UAE, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Applied Materials, ULVAC, Lam Research, Buhler, Optorun, Aixtron SE, Evatec, Shincron, Von Ardenne, IHI. |

| Key Drivers | • Rapid technological progress. • Its used in a wide range of domains. |

| Restraints | • High initial investment costs. • lack of technically skilled labor. |

Ans. The Vacuum Coating Machine Market size is forecasted to surpass USD 54.7billion by 2031.

Ans. The expected CAGR of the Vacuum Coating Machine Market during the forecast period is 9.2%.

Ans: The Asia Pacific region currently dominates the vacuum coating machine market and is projected to do so for the foreseeable future.

Ans: - The major key players are Applied Materials, ULVAC, Lam Research, Buhler, Optorun, Aixtron SE, Evatec, Shincron, Von Ardenne, IHI.

Ans: - The study includes a comprehensive analysis of Vacuum Coating Machine Market trends, as well as present and future market forecasts. DROC analysis, as well as impact analysis for the projected period. Porter's five forces analysis aids in the study of buyer and supplier potential as well as the competitive landscape etc.

TABLE OF CONTENTS

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Industry Flowchart

3. Research Methodology

4. Market Dynamics

4.1 Drivers

4.2 Restraints

4.3 Opportunities

4.4 Challenges

5. Impact Analysis

5.1 Impact of Russia-Ukraine Crisis

5.2 Impact of Economic Slowdown on Major Countries

5.2.1 Introduction

5.2.2 United States

5.2.3 Canada

5.2.4 Germany

5.2.5 France

5.2.6 UK

5.2.7 China

5.2.8 Japan

5.2.9 South Korea

5.2.10 India

6. Value Chain Analysis

7. Porter’s 5 Forces Model

8. Pest Analysis

9. Vacuum Coating Machine Market, By Process

9.1 Introduction

9.2 Trend Analysis

9.3 Physical Vapor Deposition (PVD)

9.4 Chemical Vapor Deposition (CVD)

10. Vacuum Coating Machine Market, By Product Type

10.1 Introduction

10.2 Trend Analysis

10.3 Vacuum Evaporation Coating Machine

10.4 Vacuum Sputtering Coating Machine

10.5 Chemical Vapor Deposition (CVD) Coating Machine

10.6 Others

11. Vacuum Coating Machine Market, By Application

11.1 Introduction

11.2 Trend Analysis

11.3 Automotive

11.4 Electronics

11.5 Packaging

11.6 Optical

11.7 Glass

11.8 Others

12. Regional Analysis

12.1 Introduction

12.2 North America

12.2.1 Trend Analysis

12.2.2 North America Vacuum Coating Machine Market, By Country

12.2.3 North America Vacuum Coating Machine Market, By Process

12.2.4 North America Vacuum Coating Machine Market, By Product Type

12.2.5 North America Vacuum Coating Machine Market, By Application

12.2.6 USA

12.2.6.1 USA Vacuum Coating Machine Market, By Process

12.2.6.2 USA Vacuum Coating Machine Market, By Product Type

12.2.6.3 USA Vacuum Coating Machine Market, By Application

12.2.7 Canada

12.2.7.1 Canada Vacuum Coating Machine Market, By Process

12.2.7.2 Canada Vacuum Coating Machine Market, By Product Type

12.2.7.3 Canada Vacuum Coating Machine Market, By Application

12.2.8 Mexico

12.2.8.1 Mexico Vacuum Coating Machine Market, By Process

12.2.8.2 Mexico Vacuum Coating Machine Market, By Product Type

12.2.8.3 Mexico Vacuum Coating Machine Market, By Application

12.3 Europe

12.3.1 Trend Analysis

12.3.2 Eastern Europe

12.3.2.1 Eastern Europe Vacuum Coating Machine Market, by Country

12.3.2.2 Eastern Europe Vacuum Coating Machine Market, By Process

12.3.2.3 Eastern Europe Vacuum Coating Machine Market, By Product Type

12.3.2.4 Eastern Europe Vacuum Coating Machine Market, By Application

12.3.2.5 Poland

12.3.2.5.1 Poland Vacuum Coating Machine Market, By Process

12.3.2.5.2 Poland Vacuum Coating Machine Market, By Product Type

12.3.2.5.3 Poland Vacuum Coating Machine Market, By Application

12.3.2.6 Romania

12.3.2.6.1 Romania Vacuum Coating Machine Market, By Process

12.3.2.6.2 Romania Vacuum Coating Machine Market, By Product Type

12.3.2.6.4 Romania Vacuum Coating Machine Market, By Application

12.3.2.7 Hungary

12.3.2.7.1 Hungary Vacuum Coating Machine Market, By Process

12.3.2.7.2 Hungary Vacuum Coating Machine Market, By Product Type

12.3.2.7.3 Hungary Vacuum Coating Machine Market, By Application

12.3.2.8 Turkey

12.3.2.8.1 Turkey Vacuum Coating Machine Market, By Process

12.3.2.8.2 Turkey Vacuum Coating Machine Market, By Product Type

12.3.2.8.3 Turkey Vacuum Coating Machine Market, By Application

12.3.2.9 Rest of Eastern Europe

12.3.2.9.1 Rest of Eastern Europe Vacuum Coating Machine Market, By Process

12.3.2.9.2 Rest of Eastern Europe Vacuum Coating Machine Market, By Product Type

12.3.2.9.3 Rest of Eastern Europe Vacuum Coating Machine Market, By Application

12.3.3 Western Europe

12.3.3.1 Western Europe Vacuum Coating Machine Market, by Country

12.3.3.2 Western Europe Vacuum Coating Machine Market, By Process

12.3.3.3 Western Europe Vacuum Coating Machine Market, By Product Type

12.3.3.4 Western Europe Vacuum Coating Machine Market, By Application

12.3.3.5 Germany

12.3.3.5.1 Germany Vacuum Coating Machine Market, By Process

12.3.3.5.2 Germany Vacuum Coating Machine Market, By Product Type

12.3.3.5.3 Germany Vacuum Coating Machine Market, By Application

12.3.3.6 France

12.3.3.6.1 France Vacuum Coating Machine Market, By Process

12.3.3.6.2 France Vacuum Coating Machine Market, By Product Type

12.3.3.6.3 France Vacuum Coating Machine Market, By Application

12.3.3.7 UK

12.3.3.7.1 UK Vacuum Coating Machine Market, By Process

12.3.3.7.2 UK Vacuum Coating Machine Market, By Product Type

12.3.3.7.3 UK Vacuum Coating Machine Market, By Application

12.3.3.8 Italy

12.3.3.8.1 Italy Vacuum Coating Machine Market, By Process

12.3.3.8.2 Italy Vacuum Coating Machine Market, By Product Type

12.3.3.8.3 Italy Vacuum Coating Machine Market, By Application

12.3.3.9 Spain

12.3.3.9.1 Spain Vacuum Coating Machine Market, By Process

12.3.3.9.2 Spain Vacuum Coating Machine Market, By Product Type

12.3.3.9.3 Spain Vacuum Coating Machine Market, By Application

12.3.3.10 Netherlands

12.3.3.10.1 Netherlands Vacuum Coating Machine Market, By Process

12.3.3.10.2 Netherlands Vacuum Coating Machine Market, By Product Type

12.3.3.10.3 Netherlands Vacuum Coating Machine Market, By Application

12.3.3.11 Switzerland

12.3.3.11.1 Switzerland Vacuum Coating Machine Market, By Process

12.3.3.11.2 Switzerland Vacuum Coating Machine Market, By Product Type

12.3.3.11.3 Switzerland Vacuum Coating Machine Market, By Application

12.3.3.1.12 Austria

12.3.3.12.1 Austria Vacuum Coating Machine Market, By Process

12.3.3.12.2 Austria Vacuum Coating Machine Market, By Product Type

12.3.3.12.3 Austria Vacuum Coating Machine Market, By Application

12.3.3.13 Rest of Western Europe

12.3.3.13.1 Rest of Western Europe Vacuum Coating Machine Market, By Process

12.3.3.13.2 Rest of Western Europe Vacuum Coating Machine Market, By Product Type

12.3.3.13.3 Rest of Western Europe Vacuum Coating Machine Market, By Application

12.4 Asia-Pacific

12.4.1 Trend Analysis

12.4.2 Asia-Pacific Vacuum Coating Machine Market, by Country

12.4.3 Asia-Pacific Vacuum Coating Machine Market, By Process

12.4.4 Asia-Pacific Vacuum Coating Machine Market, By Product Type

12.4.5 Asia-Pacific Vacuum Coating Machine Market, By Application

12.4.6 China

12.4.6.1 China Vacuum Coating Machine Market, By Process

12.4.6.2 China Vacuum Coating Machine Market, By Product Type

12.4.6.3 China Vacuum Coating Machine Market, By Application

12.4.7 India

12.4.7.1 India Vacuum Coating Machine Market, By Process

12.4.7.2 India Vacuum Coating Machine Market, By Product Type

12.4.7.3 India Vacuum Coating Machine Market, By Application

12.4.8 Japan

12.4.8.1 Japan Vacuum Coating Machine Market, By Process

12.4.8.2 Japan Vacuum Coating Machine Market, By Product Type

12.4.8.3 Japan Vacuum Coating Machine Market, By Application

12.4.9 South Korea

12.4.9.1 South Korea Vacuum Coating Machine Market, By Process

12.4.9.2 South Korea Vacuum Coating Machine Market, By Product Type

12.4.9.3 South Korea Vacuum Coating Machine Market, By Application

12.4.10 Vietnam

12.4.10.1 Vietnam Vacuum Coating Machine Market, By Process

12.4.10.2 Vietnam Vacuum Coating Machine Market, By Product Type

12.4.10.3 Vietnam Vacuum Coating Machine Market, By Application

12.4.11 Singapore

12.4.11.1 Singapore Vacuum Coating Machine Market, By Process

12.4.11.2 Singapore Vacuum Coating Machine Market, By Product Type

12.4.11.3 Singapore Vacuum Coating Machine Market, By Application

12.4.12 Australia

12.4.12.1 Australia Vacuum Coating Machine Market, By Process

12.4.12.2 Australia Vacuum Coating Machine Market, By Product Type

12.4.12.3 Australia Vacuum Coating Machine Market, By Application

12.4.13 Rest of Asia-Pacific

12.4.13.1 Rest of Asia-Pacific Vacuum Coating Machine Market, By Process

12.4.13.2 Rest of Asia-Pacific Vacuum Coating Machine Market, By Product Type

12.4.13.3 Rest of Asia-Pacific Vacuum Coating Machine Market, By Application

12.5 Middle East & Africa

12.5.1 Trend Analysis

12.5.2 Middle East

12.5.2.1 Middle East Vacuum Coating Machine Market, by Country

12.5.2.2 Middle East Vacuum Coating Machine Market, By Process

12.5.2.3 Middle East Vacuum Coating Machine Market, By Product Type

12.5.2.4 Middle East Vacuum Coating Machine Market, By Application

12.5.2.5 UAE

12.5.2.5.1 UAE Vacuum Coating Machine Market, By Process

12.5.2.5.2 UAE Vacuum Coating Machine Market, By Product Type

12.5.2.5.3 UAE Vacuum Coating Machine Market, By Application

12.5.2.6 Egypt

12.5.2.6.1 Egypt Vacuum Coating Machine Market, By Process

12.5.2.6.2 Egypt Vacuum Coating Machine Market, By Product Type

12.5.2.6.3 Egypt Vacuum Coating Machine Market, By Application

12.5.2.7 Saudi Arabia

12.5.2.7.1 Saudi Arabia Vacuum Coating Machine Market, By Process

12.5.2.7.2 Saudi Arabia Vacuum Coating Machine Market, By Product Type

12.5.2.7.3 Saudi Arabia Vacuum Coating Machine Market, By Application

12.5.2.8 Qatar

12.5.2.8.1 Qatar Vacuum Coating Machine Market, By Process

12.5.2.8.2 Qatar Vacuum Coating Machine Market, By Product Type

12.5.2.8.3 Qatar Vacuum Coating Machine Market, By Application

12.5.2.9 Rest of Middle East

12.5.2.9.1 Rest of Middle East Vacuum Coating Machine Market, By Process

12.5.2.9.2 Rest of Middle East Vacuum Coating Machine Market, By Product Type

12.5.2.9.3 Rest of Middle East Vacuum Coating Machine Market, By Application

12.5.3 Africa

12.5.3.1 Africa Vacuum Coating Machine Market, by Country

12.5.3.2 Africa Vacuum Coating Machine Market, By Process

12.5.3.3 Africa Vacuum Coating Machine Market, By Product Type

12.5.3.4 Africa Vacuum Coating Machine Market, By Application

12.5.3.5 Nigeria

12.5.3.5.1 Nigeria Vacuum Coating Machine Market, By Process

12.5.3.5.2 Nigeria Vacuum Coating Machine Market, By Product Type

12.5.3.5.3 Nigeria Vacuum Coating Machine Market, By Application

12.5.3.6 South Africa

12.5.3.6.1 South Africa Vacuum Coating Machine Market, By Process

12.5.3.6.2 South Africa Vacuum Coating Machine Market, By Product Type

12.5.3.6.3 South Africa Vacuum Coating Machine Market, By Application

12.5.3.7 Rest of Africa

12.5.3.7.1 Rest of Africa Vacuum Coating Machine Market, By Process

12.5.3.7.2 Rest of Africa Vacuum Coating Machine Market, By Product Type

12.5.3.7.3 Rest of Africa Vacuum Coating Machine Market, By Application

12.6 Latin America

12.6.1 Trend Analysis

12.6.2 Latin America Vacuum Coating Machine Market, by country

12.6.3 Latin America Vacuum Coating Machine Market, By Process

12.6.4 Latin America Vacuum Coating Machine Market, By Product Type

12.6.5 Latin America Vacuum Coating Machine Market, By Application

12.6.6 Brazil

12.6.6.1 Brazil Vacuum Coating Machine Market, By Process

12.6.6.2 Brazil Vacuum Coating Machine Market, By Product Type

12.6.6.3 Brazil Vacuum Coating Machine Market, By Application

12.6.7 Argentina

12.6.7.1 Argentina Vacuum Coating Machine Market, By Process

12.6.7.2 Argentina Vacuum Coating Machine Market, By Product Type

12.6.7.3 Argentina Vacuum Coating Machine Market, By Application

12.6.8 Colombia

12.6.8.1 Colombia Vacuum Coating Machine Market, By Process

12.6.8.2 Colombia Vacuum Coating Machine Market, By Product Type

12.6.8.3 Colombia Vacuum Coating Machine Market, By Application

12.6.9 Rest of Latin America

12.6.9.1 Rest of Latin America Vacuum Coating Machine Market, By Process

12.6.9.2 Rest of Latin America Vacuum Coating Machine Market, By Product Type

12.6.9.3 Rest of Latin America Vacuum Coating Machine Market, By Application

13.Company Profiles

13.1 Aixtron SE

13.1.1 Company Overview

13.1.2 Financial

13.1.3Products/ Services Offered

13.1.4 SWOT Analysis

13.1.5 The SNS View

13.2 Applied Materials Inc.

13.2.1 Company Overview

13.2.2 Financial

13.2.3Products/ Services Offered

13.2.4 SWOT Analysis

13.2.5 The SNS View

13.3 Buhler Leybold Optics.

13.3.1 Company Overview

13.3.2 Financial

13.3.3Products/ Services Offered

13.3.4 SWOT Analysis

13.3.5 The SNS View

13.4 Optorun.

13.4.1 Company Overview

13.4.2 Financial

13.4.3Products/ Services Offered

13.4.4 SWOT Analysis

13.4.5 The SNS View

13.5 Shincron Co. Ltd.

13.5.1 Company Overview

13.5.2 Financial

13.5.3Products/ Services Offered

13.5.4 SWOT Analysis

13.5.5 The SNS View

13.6 Von Ardenne GmbH

13.6.1 Company Overview

13.6.2 Financial

13.6.3Products/ Services Offered

13.6.4 SWOT Analysis

13.6.5 The SNS View

13.7 ULVAC Technologies Inc.

13.7.1 Company Overview

13.7.2 Financial

13.7.3Products/ Services Offered

13.7.4 SWOT Analysis

13.7.5 The SNS View

13.8 Hanil Vacuum Co. Ltd.

13.8.1 Company Overview

13.8.2 Financial

13.8.3 Products/ Services Offered

13.8.4 SWOT Analysis

13.8.5 The SNS View

13.9 IHI HAUZER B.V.

13.9.1 Company Overview

13.9.2 Financial

13.9.3 Products/ Services Offered

13.9.4 SWOT Analysis

13.9.5 The SNS View

13.10 Denton Vacuum LLC

13.10.1 Company Overview

13.10.2 Financial

13.10.3 Products/ Services Offered

13.10.4 SWOT Analysis

13.10.5 The SNS View

14. Competitive Landscape

14.1 Competitive Benchmarking

14.2 Market Share Analysis

14.3 Recent Developments

14.3.1 Industry News

14.3.2 Company News

14.3.3 Mergers & Acquisitions

15. Use Case and Best Practices

16. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

The Gas Leak Detector Market Size was valued at USD 5.06 Billion in 2023 and is now anticipated to grow to USD 8.84 Billion by 2032, displaying a compound annual growth rate (CAGR) of 6.4% during the forecast Period 2024-2032.

Compressor Rental Market was estimated at USD 4.47 Bn in 2023 and is expected to reach USD 7.64 Bn by 2032, with a growing CAGR of 6.14% from 2024 to 2032.

The Cranes Market Size was estimated at USD 46.59 billion in 2023 and is expected to arrive at USD 74.93 billion by 2032 with a growing CAGR of 5.42% over the forecast period 2024-2032.

Decanter Centrifuge Market was esteemed at USD 2.30 billion in 2023 and is supposed to arrive at USD 3.52 billion by 2032, growing CAGR of 4.84% from 2024-2032.

The Rotary Pumps Market size was valued at USD 7.85 Billion in 2023 and is now anticipated to grow to USD 11.26 Billion by 2032, displaying a compound annual growth rate (CAGR) of 3.68% during the forecast Period 2024-2032.

The Mass Flow Controller Market Size was valued at USD 1.32 Billion in 2023 and will Reach to $2.16 Billion by 2031, displaying a CAGR of 5.61% by 2024-2031.

Hi! Click one of our member below to chat on Phone