Get more information on Robotic Vision Market - Request Sample Report

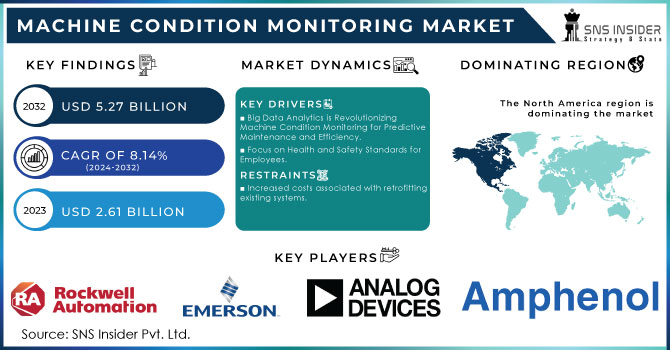

The Machine Condition Monitoring Market size was valued at USD 2.61 Billion in 2023. It is estimated to reach USD 5.27 Billion by 2032, growing at a CAGR of 8.14% during 2024-2032.

The machine condition monitoring market is now a vital industrial sector, supported by the growing demand for efficiency, reliability, and cost savings in equipment. The rise of the machine condition monitoring market is greatly impacted by the growing usage of Industry 4.0 and the Industrial Internet of Things (IIoT). The expansion of Industry 4.0 is fueled by large financial investments, with an estimated global spending of approximately USD 60 billion in 2023. The manufacturing sector depends greatly on sophisticated equipment like CNC machines, conveyors, and industrial robots to keep production flowing. About 70% of manufacturing firms are allocating resources towards Industry 4.0 technologies to improve both operational effectiveness and quality of products. Despite big companies taking the lead, roughly 35% of small and medium-sized businesses (SMEs) are also incorporating Industry 4.0 technologies, showing a wider range of acceptance. With automation and digitalization being adopted globally by industries, the incorporation of advanced sensors, data analytics, and machine learning algorithms into monitoring systems is becoming increasingly common. Manufacturers can detect issues early, plan maintenance during scheduled downtimes, and prevent disruptions by using condition monitoring systems.

AI improves condition-based monitoring by utilizing sophisticated algorithms and machine learning to assess large quantities of data gathered from different sensors. The implementation of AI in maintenance can reduce maintenance costs by up to 20%. This evaluation allows the system to identify patterns and irregularities that could signal potential problems. AI-powered solutions can forecast equipment malfunctions more accurately and quickly than traditional approaches, resulting in improved maintenance tactics. For instance, IBM's Watson IoT platform utilizes AI for predictive maintenance by analyzing sensor data from equipment. This enables businesses to predict potential failures and optimize maintenance schedules, reducing downtime and maintenance costs. The inclusion of AI enables the automation of monitoring tasks, ensuring constant monitoring of equipment health without the requirement of human involvement. This leads to enhanced operational efficiency and decreased human error. Moreover, AI can improve maintenance plans by forecasting when machinery will need maintenance, leading to reduced unnecessary checkups and longer equipment lifespan. AI supports businesses in improving equipment reliability, cutting costs, and boosting overall operational performance through actionable insights and automated monitoring tasks.

Drivers

Big Data Analytics is Revolutionizing Machine Condition Monitoring for Predictive Maintenance and Efficiency.

The rise of Big Data Analytics is a key factor in driving the Machine Condition Monitoring Market. Big Data Analytics allows for the examination and interpretation of large volumes of data produced by machines and industrial systems, providing access to insights that were previously out of reach. With the rising adoption of smart manufacturing and the IIoT, machines now come equipped with various sensors to continually track factors like temperature, vibration, and pressure. When combined and examined, the data from this sensor can uncover trends and irregularities that suggest wear and tear on the machine, possible breakdowns, or inefficiencies. The use of Big Data Analytics enables the immediate examination of the data, which results in the development of maintenance strategies that can predict future issues. Industries no longer need to stick to scheduled maintenance; instead, they can predict failures in advance to decrease downtime and maintenance expenses substantially. Furthermore, it helps improve machine efficiency and prolong equipment lifespan through actionable insights derived from historical data patterns.

Focus on Health and Safety Standards for Employees.

Employee health and safety standards are essential in the Machine Condition Monitoring (MCM) market. Businesses are striving to improve workplace safety and reduce risks related to machine operations through the adoption and advancement of MCM technologies. Machine Condition Monitoring is the ongoing evaluation of equipment to identify and resolve possible problems before they become serious. This proactive strategy not only increases the durability of equipment but also greatly lowers the likelihood of accidents and injuries. By incorporating MCM systems, businesses can guarantee proper operation of machinery, thus averting dangerous malfunctions that may result in safety incidents. Adherence to health and safety rules requires employers to put in place safeguards for their employees. MCM systems help with compliance by allowing for real-time monitoring of equipment conditions, detecting signs of deterioration, and arranging maintenance when needed. This helps decrease the chances of sudden malfunctions that could potentially create safety hazards.

Restraints

Increased costs associated with retrofitting existing systems.

Higher expenses linked to updating current systems are a major obstacle in the Machine Condition Monitoring Market. Retrofitting includes enhancing or adjusting current machinery and systems to incorporate advanced condition monitoring technologies. Although these enhancements may improve the system's performance and reliability, the associated expenses may be too high for numerous organizations. The retrofitting process involves purchasing new sensors and monitoring equipment, as well as extensive installation and integration efforts. This involves adjusting the new systems to function smoothly with outdated equipment, which frequently necessitates specific skills and technical know-how. The expenses can increase even more due to the requirement of system downtime for installation, resulting in possible production setbacks. Furthermore, the intricacy of retrofitting may lead to unforeseen costs for adjusting the current infrastructure to support new technologies. Organizations could encounter difficulties like incompatibility between old and new parts or the requirement for extra changes to current systems. These factors add to a substantial financial load, posing a challenge for businesses to rationalize investing in upgrades for condition monitoring.

By Technique

Vibration monitoring captured 35% of revenue share in 2023 and dominated the market. This method is essential for identifying disparities, misalignments, and other mechanical problems in rotating equipment such as motors, pumps, and turbines. Through the analysis of vibration data, organizations can anticipate equipment malfunctions and conduct maintenance before expensive breakdowns take place. Sectors like oil and gas, manufacturing, and power generation depend greatly on vibration monitoring for maintaining efficiency and minimizing downtime. General Electric (GE) utilizes vibration monitoring extensively in its power plants as a means of ensuring the reliability of turbines and generators.

Ultrasound Emission Monitoring is going to be the fastest-growing segment during the forecast period 2024-2032, as it can identify faults and energy inefficiencies in their early stages, which other techniques may overlook. This method works well at spotting problems in compressed air systems, steam traps, and electrical equipment, so it is widely used in industries that prioritize energy efficiency and sustainability. Businesses are increasingly utilizing ultrasound emission monitoring for predictive maintenance because it enables non-intrusive inspections during equipment operation. Emerson Electric Co. uses ultrasound technology in its machinery health solutions to assist customers in the automotive and aerospace industries by identifying leaks, bearing failures, and electrical faults at an early stage.

By Deployment

The On-Cloud segment led the market in 2023 with a 55% market share, due to its scalability, flexibility, and cost-effectiveness. Cloud-based solutions provide the ability to access real-time data remotely, improving the monitoring and management of machine statuses. The section gains from progress in cloud computing and IoT technologies that improve the precision and timeliness of condition monitoring. GE Digital uses cloud-based technology for its Predix platform, providing real-time monitoring of machines and predictive analysis. This system assists in enhancing machine efficiency and avoiding breakdowns by analyzing information gathered from different sensors in industries.

The On-Premises segment is expected to grow at a faster CAGR during the forecast period. Organizations that choose on-premises solutions enjoy keeping their data in their infrastructure, which is important for compliance and security purposes. Siemens offers on-site condition monitoring solutions with its Siemens Condition Monitoring System, providing extensive diagnostic and monitoring features for industrial equipment. This system is utilized in settings that necessitate strict data security and operational management.

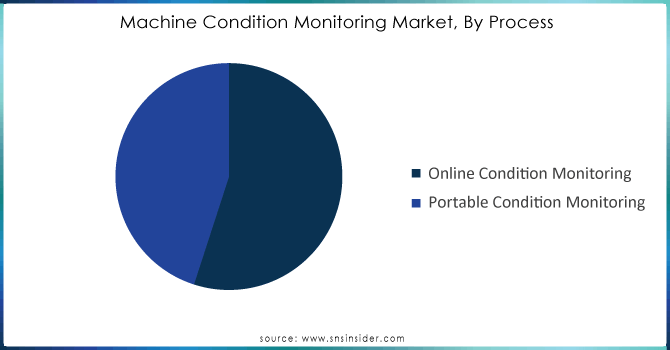

By Process

Online Condition Monitoring captured a major market share of more than 54% in 2023. This includes placing sensors and monitoring systems on equipment to continuously analyze variables like vibration, temperature, and acoustic emissions. This method enables the detection of possible problems at an early stage, reducing downtime and improving maintenance schedules. The section is influential because it offers ongoing insights, improving predictive maintenance tactics and minimizing unforeseen breakdowns.

Portable Condition Monitoring is the practice of utilizing handheld or portable gadgets to evaluate the state of equipment at different spots or moments. This approach is commonly utilized for scheduled checks as opposed to constant surveillance. It enables maintenance staff to conduct thorough inspections and diagnostic assessments, offering versatility in overseeing different machines without requiring a permanent setup. While not as consistent as online systems, it provides a cost-efficient alternative for smaller businesses or for evaluating equipment that doesn't require constant monitoring.

Get Customized Report as per your Business Requirement - Request For Customized Report

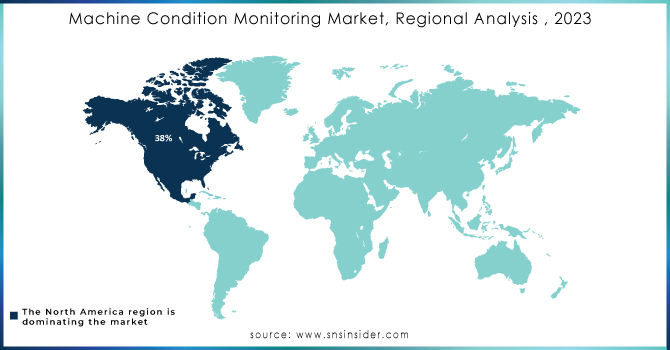

North America dominated the market in 2023 with a revenue share of 38%, due to its sophisticated industrial foundation and quick acceptance of state-of-the-art technologies. The area's focus on using predictive maintenance to decrease downtime and enhance operational efficiency in industries like oil and gas, aerospace, and manufacturing has increased the need for machine condition monitoring systems. The market is further reinforced by the participation of major companies such as General Electric, Emerson Electric, and Honeywell in the United States. These businesses provide cutting-edge solutions like vibration monitoring and infrared thermography to assist companies in reaching optimal machine performance.

Asia-Pacific is accounted to have a faster growth rate during 2024-2032, due to quick industrialization and infrastructure development in countries such as China, India, and Japan. The growth of the manufacturing industry in the area, along with a growing understanding of the advantages of predictive maintenance, is driving the utilization of machine condition monitoring solutions. Major sectors such as automobile, energy production, and chemical industries are putting money into these technologies in order to boost efficiency and lower operational expenses. Corporations such as SKF and Siemens have been actively implementing their condition-monitoring solutions in the area, meeting the increasing need for real-time data analysis and remote monitoring.

The key players in the Global Machine Condition Monitoring market are Emerson Electric Co, Rockwell Automation Inc, Analog Devices Inc, Amphenol Inc., National Instruments Corp, Fluke Corporation, General Electric, Parker Hannifin Corp, SKF, Allied Reliability, Meggitt PLC and other.

In January 2024, SKF launched the Enlight AI machine condition monitoring system, which utilizes artificial intelligence to predict equipment failures before they happen. This system is designed to improve efficiency and reduce downtime in industrial applications by continuously monitoring machine health.

In September 2024, Fluke introduced the 3561 FC vibration sensor as part of its connected reliability ecosystem. This sensor monitors vibration levels in industrial equipment, allowing maintenance teams to detect early signs of mechanical issues and schedule repairs before they escalate.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 2.61 Billion |

| Market Size by 2032 | USD 5.27 Billion |

| CAGR | CAGR of 8.14% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Technique (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission Monitoring, Motor Current Analysis) • By Deployment (On-Cloud, On-Premises) • By Process (Online Condition Monitoring, Portable Condition Monitoring) • By Industry (Oil & Gas, Metal & Mining, Automotive, Food & Beverages, Power Generation, Chemicals, Aerospace, Marine, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Emerson Electric Co, Rockwell Automation Inc, Analog Devices Inc., Amphenol Inc., National Instruments Corp, Fluke Corporation, General Electric, Parker Hannifin Corp, SKF, Allied Reliability, Meggitt PLC |

| Key Drivers | • Big Data Analytics is Revolutionizing Machine Condition Monitoring for Predictive Maintenance and Efficiency. • Focus on Health and Safety Standards for Employees. |

| Restraints | • Increased costs associated with retrofitting existing systems. |

Ans: The Machine Condition Monitoring Market is expected to grow at a CAGR of 8.14% during 2024-2032.

Ans: Machine Condition Monitoring Market size was USD 2.61 Billion in 2023 and is expected to Reach USD 5.27 Billion by 2032.

Ans: Big Data Analytics is Revolutionizing Machine Condition Monitoring for Predictive Maintenance and Efficiency.

Ans: The on-premises segment dominated the Machine Condition Monitoring Market.

Ans: North America dominated the Machine Condition Monitoring Market in 2023.

Table of Content

1. Introduction

1.1 Market Definition

1.2 Scope (Inclusion and Exclusions)

1.3 Research Assumptions

2. Executive Summary

2.1 Market Overview

2.2 Regional Synopsis

2.3 Competitive Summary

3. Research Methodology

3.1 Top-Down Approach

3.2 Bottom-up Approach

3.3. Data Validation

3.4 Primary Interviews

4. Market Dynamics Impact Analysis

4.1 Market Driving Factors Analysis

4.1.1 Drivers

4.1.2 Restraints

4.1.3 Opportunities

4.1.4 Challenges

4.2 PESTLE Analysis

4.3 Porter’s Five Forces Model

5. Statistical Insights and Trends Reporting

5.1 Machine Condition Monitoring Key Vendors and Feature Analysis, 2023

5.2 Machine Condition Monitoring Performance Benchmarks, 2023

5.3 Machine Condition Monitoring Integration Capabilities, by Software

5.4 Usage Statistics, 2023

6. Competitive Landscape

6.1 List of Major Companies, By Region

6.2 Market Share Analysis, By Region

6.3 Product Benchmarking

6.3.1 Product specifications and features

6.3.2 Pricing

6.4 Strategic Initiatives

6.4.1 Marketing and promotional activities

6.4.2 Distribution and Supply Chain Strategies

6.4.3 Expansion plans and new product launches

6.4.4 Strategic partnerships and collaborations

6.5 Technological Advancements

6.6 Market Positioning and Branding

7. Machine Condition Monitoring Market Segmentation, by Technique

7.1 Chapter Overview

7.2 Vibration Monitoring

7.2.1 Vibration Monitoring Market Trends Analysis (2020-2032)

7.2.2 Vibration Monitoring Market Size Estimates and Forecasts to 2032 (USD Billion)

7.3 Thermography

7.3.1 Thermography Market Trends Analysis (2020-2032)

7.3.2 Thermography Market Size Estimates and Forecasts to 2032 (USD Billion)

7.4 Oil Analysis

7.4.1 Oil Analysis Market Trends Analysis (2020-2032)

7.4.2 Oil Analysis Market Size Estimates and Forecasts to 2032 (USD Billion)

7.5 Corrosion Monitoring

7.5.1 Corrosion Monitoring Market Trends Analysis (2020-2032)

7.5.2 Corrosion Monitoring Market Size Estimates and Forecasts to 2032 (USD Billion)

7.6 Ultrasound Emission Monitoring

7.6.1 Ultrasound Emission Monitoring Market Trends Analysis (2020-2032)

7.6.2 Ultrasound Emission Monitoring Market Size Estimates and Forecasts to 2032 (USD Billion)

7.7 Motor Current Analysis

7.7.1 Motor Current Analysis Market Trends Analysis (2020-2032)

7.7.2 Motor Current Analysis Market Size Estimates and Forecasts to 2032 (USD Billion)

8. Machine Condition Monitoring Market Segmentation, by Deployment

8.1 Chapter Overview

8.2 On-Cloud

8.2.1 On-Cloud Market Trends Analysis (2020-2032)

8.2.2 On-Cloud Market Size Estimates and Forecasts to 2032 (USD Billion)

8.3 On-Premises

8.3.1 On-Premises Market Trends Analysis (2020-2032)

8.3.2 On-Premises Market Size Estimates and Forecasts to 2032 (USD Billion)

9. Machine Condition Monitoring Market Segmentation, by Process

9.1 Chapter Overview

9.2 Online Condition Monitoring

9.2.1 Online Condition Monitoring Market Trends Analysis (2020-2032)

9.2.2 Online Condition Monitoring Market Size Estimates and Forecasts to 2032 (USD Billion)

9.3 Portable Condition Monitoring

9.3.1 Portable Condition Monitoring Market Trends Analysis (2020-2032)

9.3.2 Portable Condition Monitoring Market Size Estimates and Forecasts to 2032 (USD Billion)

10. Machine Condition Monitoring Market Segmentation, by Industry

10.1 Chapter Overview

10.2 Oil & Gas

10.2.1 Oil & Gas Market Trends Analysis (2020-2032)

10.2.2 Oil & Gas Market Size Estimates and Forecasts to 2032 (USD Billion)

10.3 Metal & Mining

10.3.1 Metal & Mining Market Trends Analysis (2020-2032)

10.3.2 Metal & Mining Market Size Estimates and Forecasts to 2032 (USD Billion)

10.4 Automotive

10.4.1 Automotive Market Trends Analysis (2020-2032)

10.4.2 Automotive Market Size Estimates and Forecasts to 2032 (USD Billion)

10.5 Food & Beverages

10.5.1 Food & Beverages Market Trends Analysis (2020-2032)

10.5.2 Food & Beverages Market Size Estimates and Forecasts to 2032 (USD Billion)

10.6 Power Generation

10.6.1 Power Generation Market Trends Analysis (2020-2032)

10.6.2 Power Generation Market Size Estimates and Forecasts to 2032 (USD Billion)

10.6 Chemicals

10.6.1 Chemicals Market Trends Analysis (2020-2032)

10.6.2 Chemicals Market Size Estimates and Forecasts to 2032 (USD Billion)

10.6 Aerospace

10.6.1 Aerospace Market Trends Analysis (2020-2032)

10.6.2 Aerospace Market Size Estimates and Forecasts to 2032 (USD Billion)

10.6 Marine

10.6.1 Marine Market Trends Analysis (2020-2032)

10.6.2 Marine Market Size Estimates and Forecasts to 2032 (USD Billion)

10.10 Others

10.10.1 Others Market Trends Analysis (2020-2032)

10.10.2 Others Market Size Estimates and Forecasts to 2032 (USD Billion)

11. Regional Analysis

11.1 Chapter Overview

11.2 North America

11.2.1 Trends Analysis

11.2.2 North America Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.2.3 North America Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.2.4 North America Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.2.5 North America Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.2.6 North America Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.2.7 USA

11.2.7.1 USA Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.2.7.2 USA Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.2.7.3 USA Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.2.7.4 USA Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.2.8 Canada

11.2.8.1 Canada Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.2.8.2 Canada Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.2.8.3 Canada Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.2.8.4 Canada Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.2.9 Mexico

11.2.9.1 Mexico Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.2.9.2 Mexico Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.2.9.3 Mexico Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.2.9.4 Mexico Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3 Europe

11.3.1 Eastern Europe

11.3.1.1 Trends Analysis

11.3.1.2 Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.3.1.3 Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.4 Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.5 Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.6 Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.1.7 Poland

11.3.1.7.1 Poland Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.7.2 Poland Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.7.3 Poland Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.7.4 Poland Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.1.8 Romania

11.3.1.8.1 Romania Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.8.2 Romania Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.8.3 Romania Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.8.4 Romania Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.1.9 Hungary

11.3.1.9.1 Hungary Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.9.2 Hungary Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.9.3 Hungary Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.9.4 Hungary Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.1.10 Turkey

11.3.1.10.1 Turkey Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.10.2 Turkey Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.10.3 Turkey Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.10.4 Turkey Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.1.11 Rest of Eastern Europe

11.3.1.11.1 Rest of Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.1.11.2 Rest of Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.1.11.3 Rest of Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.1.11.4 Rest of Eastern Europe Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2 Western Europe

11.3.2.1 Trends Analysis

11.3.2.2 Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.3.2.3 Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.4 Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.5 Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.6 Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.7 Germany

11.3.2.7.1 Germany Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.7.2 Germany Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.7.3 Germany Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.7.4 Germany Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.8 France

11.3.2.8.1 France Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.8.2 France Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.8.3 France Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.8.4 France Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.9 UK

11.3.2.9.1 UK Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.9.2 UK Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.9.3 UK Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.9.4 UK Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.10 Italy

11.3.2.10.1 Italy Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.10.2 Italy Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.10.3 Italy Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.10.4 Italy Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.11 Spain

11.3.2.11.1 Spain Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.11.2 Spain Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.11.3 Spain Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.11.4 Spain Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.12 Netherlands

11.3.2.12.1 Netherlands Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.12.2 Netherlands Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.12.3 Netherlands Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.12.4 Netherlands Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.13 Switzerland

11.3.2.13.1 Switzerland Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.13.2 Switzerland Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.13.3 Switzerland Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.13.4 Switzerland Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.14 Austria

11.3.2.14.1 Austria Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.14.2 Austria Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.14.3 Austria Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.14.4 Austria Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.3.2.15 Rest of Western Europe

11.3.2.15.1 Rest of Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.3.2.15.2 Rest of Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.3.2.15.3 Rest of Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.3.2.15.4 Rest of Western Europe Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4 Asia Pacific

11.4.1 Trends Analysis

11.4.2 Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.4.3 Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.4 Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.5 Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.6 Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.7 China

11.4.7.1 China Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.7.2 China Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.7.3 China Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.7.4 China Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.8 India

11.4.8.1 India Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.8.2 India Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.8.3 India Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.8.4 India Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.9 Japan

11.4.9.1 Japan Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.9.2 Japan Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.9.3 Japan Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.9.4 Japan Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.10 South Korea

11.4.10.1 South Korea Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.10.2 South Korea Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.10.3 South Korea Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.10.4 South Korea Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.11 Vietnam

11.4.11.1 Vietnam Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.11.2 Vietnam Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.11.3 Vietnam Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.11.4 Vietnam Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.12 Singapore

11.4.12.1 Singapore Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.12.2 Singapore Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.12.3 Singapore Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.12.4 Singapore Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.13 Australia

11.4.13.1 Australia Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.13.2 Australia Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.13.3 Australia Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.13.4 Australia Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.4.14 Rest of Asia Pacific

11.4.14.1 Rest of Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.4.14.2 Rest of Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.4.14.3 Rest of Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.4.14.4 Rest of Asia Pacific Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5 Middle East and Africa

11.5.1 Middle East

11.5.1.1 Trends Analysis

11.5.1.2 Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.5.1.3 Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.4 Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.5 Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.6 Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.1.7 UAE

11.5.1.7.1 UAE Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.7.2 UAE Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.7.3 UAE Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.7.4 UAE Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.1.8 Egypt

11.5.1.8.1 Egypt Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.8.2 Egypt Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.8.3 Egypt Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.8.4 Egypt Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.1.9 Saudi Arabia

11.5.1.9.1 Saudi Arabia Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.9.2 Saudi Arabia Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.9.3 Saudi Arabia Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.9.4 Saudi Arabia Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.1.10 Qatar

11.5.1.10.1 Qatar Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.10.2 Qatar Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.10.3 Qatar Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.10.4 Qatar Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.1.11 Rest of Middle East

11.5.1.11.1 Rest of Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.1.11.2 Rest of Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.1.11.3 Rest of Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.1.11.4 Rest of Middle East Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.2 Africa

11.5.2.1 Trends Analysis

11.5.2.2 Africa Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.5.2.3 Africa Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.2.4 Africa Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.2.5 Africa Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.2.6 Africa Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.2.7 South Africa

11.5.2.7.1 South Africa Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.2.7.2 South Africa Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.2.7.3 South Africa Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.2.7.4 South Africa Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.2.8 Nigeria

11.5.2.8.1 Nigeria Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.2.8.2 Nigeria Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.2.8.3 Nigeria Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.2.8.4 Nigeria Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.5.2.9 Rest of Africa

11.5.2.9.1 Rest of Africa Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.5.2.9.2 Rest of Africa Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.5.2.9.3 Rest of Africa Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.5.2.9.4 Rest of Africa Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.6 Latin America

11.6.1 Trends Analysis

11.6.2 Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.6.3 Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.6.4 Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.6.5 Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.6.6 Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.6.7 Brazil

11.6.7.1 Brazil Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.6.7.2 Brazil Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.6.7.3 Brazil Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.6.7.4 Brazil Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.6.8 Argentina

11.6.8.1 Argentina Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.6.8.2 Argentina Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.6.8.3 Argentina Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.6.8.4 Argentina Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.6.9 Colombia

11.6.9.1 Colombia Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.6.9.2 Colombia Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.6.9.3 Colombia Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.6.9.4 Colombia Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

11.6.10 Rest of Latin America

11.6.10.1 Rest of Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Technique (2020-2032) (USD Billion)

11.6.10.2 Rest of Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Deployment (2020-2032) (USD Billion)

11.6.10.3 Rest of Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Process (2020-2032) (USD Billion)

11.6.10.4 Rest of Latin America Machine Condition Monitoring Market Estimates and Forecasts, by Industry (2020-2032) (USD Billion)

12. Company Profiles

12.1 Emerson Electric Co

12.1.1 Company Overview

12.1.2 Financial

12.1.3 Products/ Services Offered

12.1.4 SWOT Analysis

12.2 Rockwell Automation Inc.

12.2.1 Company Overview

12.2.2 Financial

12.2.3 Products/ Services Offered

12.2.4 SWOT Analysis

12.3 Analog Devices Inc.

12.3.1 Company Overview

12.3.2 Financial

12.3.3 Products/ Services Offered

12.3.4 SWOT Analysis

12.4 Amphenol Inc.

12.4.1 Company Overview

12.4.2 Financial

12.4.3 Products/ Services Offered

12.4.4 SWOT Analysis

12.5 National Instruments Corp

12.5.1 Company Overview

12.5.2 Financial

12.5.3 Products/ Services Offered

12.5.4 SWOT Analysis

12.6 Fluke Corporation

12.6.1 Company Overview

12.6.2 Financial

12.6.3 Products/ Services Offered

12.6.4 SWOT Analysis

12.7 General Electric

12.7.1 Company Overview

12.7.2 Financial

12.7.3 Products/ Services Offered

12.7.4 SWOT Analysis

12.8 Parker Hannifin Corp

12.8.1 Company Overview

12.8.2 Financial

12.8.3 Products/ Services Offered

12.8.4 SWOT Analysis

12.9 SKF

12.9.1 Company Overview

12.9.2 Financial

12.9.3 Products/ Services Offered

12.9.4 SWOT Analysis

12.10 Allied Reliability

12.10.1 Company Overview

12.10.2 Financial

12.10.3 Products/ Services Offered

12.10.4 SWOT Analysis

13. Use Cases and Best Practices

14. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

By Technique

Vibration Monitoring

Thermography

Oil Analysis

Corrosion Monitoring

Ultrasound Emission Monitoring

Motor Current Analysis

By Deployment

On-Cloud

On-Premises

By Process

Online Condition Monitoring

Portable Condition Monitoring

By Industry

Oil & Gas

Metal & Mining

Oil & Gas

Food & Beverages

Power Generation

Chemicals

Aerospace

Marine

Others

Request for Segment Customization as per your Business Requirement: Segment Customization Request

REGIONAL COVERAGE:

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of the Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Request for Country Level Research Report: Country Level Customization Request

Available Customization

With the given market data, SNS Insider offers customization as per the company’s specific needs. The following customization options are available for the report:

Product Analysis

Criss-Cross segment analysis (e.g. Product X Application)

Product Matrix which gives a detailed comparison of the product portfolio of each company

Geographic Analysis

Additional countries in any of the regions

Company Information

Detailed analysis and profiling of additional market players (Up to five)

The Embedded Antenna Systems Market Size was valued at USD 3.32 billion in 2023 and is expected to reach USD 10.97 billion by 2032, growing at a CAGR of 14.2% over the forecast period 2024-2032.

The Sports Devices Market Size was valued at USD 3.65 Billion in 2023 and is expected to grow at a CAGR of 13.69% to reach USD 11.55 Billion by 2032.

The Video Measuring System Market Size was valued at USD 0.66 Billion in 2023 and is projected to grow at a CAGR of 5.23% to reach USD 1.38 Billion by 2032

The GPS Tracking Device Market was valued at USD 3.17 billion in 2023 and is expected to reach USD 10.03 billion by 2032, growing at a CAGR of 13.69% over the forecast period 2024-2032.

The Membrane Air Dryers Market Size was valued at USD 0.88 Billion in 2023 and is expected to grow at a CAGR of 6.9% to reach USD 1.60 Billion by 2032.

The Radar Sensors for Smart City Applications Market was valued at USD 248.7 Million in 2023 and is expected to reach USD 701.9 Million by 2032, growing at a CAGR of 12.24% from 2024-2032.

Hi! Click one of our member below to chat on Phone