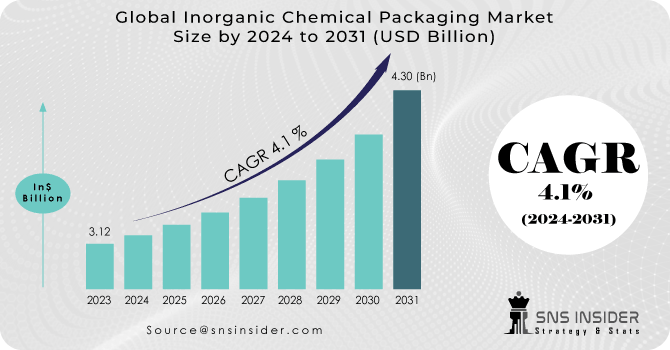

The Inorganic Chemical Packaging Market Size was valued at USD 3.12 billion in 2023 and is expected to reach USD 4.30 billion by 2031 and grow at a CAGR of 4.1 % over the forecast period 2024-2031.

The Inorganic Chemical Packaging Market provides specialized packaging solutions for the storage, transportation, and handling of non-carbon-based chemicals. These chemicals are vital across industries like manufacturing, agriculture, healthcare, and construction. Proper packaging is crucial to ensure safety, regulatory compliance, and product integrity throughout the supply chain. It involves containers, drums, totes, and specialized materials designed to resist corrosion, prevent leakage, and protect against external factors like moisture and temperature changes. Inorganic chemical packaging is essential in the chemical industry for safeguarding human health, the environment, and chemical quality. Tailored packaging solutions are necessary to accommodate diverse chemical properties, ensuring safe and optimal transport. Compliance with strict regulations is crucial for risk management and responsible chemical handling practices.

Get More Information on Inorganic Chemical Packaging Market - Request Sample Report

Packaging inorganic chemicals poses significant challenges due to the variety of compounds and potential risks involved. Inadequate packaging can render chemicals useless, harm the environment, or endanger users and warehouse staff. Proper packaging plays a crucial role in ensuring the safe handling and storage of these chemicals, preventing accidents and fatalities such as fire explosions. Inorganic chemicals, which lack carbon and may include elements like carbon monoxide and carbon dioxide, drive market growth, particularly in the fertilizers sector. China and India, known for low labor costs, attract international production hubs, reducing overall manufacturing costs. Increasing environmental awareness and stricter regulations drive companies to adopt eco-friendly technologies and products.

KEY DRIVERS:

The demand for shrink drum liners in the packaging of inorganic chemicals is on the rise.

Expansion of production capacities across different end-use sectors like food and beverages and chemical processing.

The surge in production capacities across several end-use industries, such as food and beverage production and chemical processing, has led to a significant rise in demand for industrial chemical packaging. This is further fueled by various new industrial applications for chemicals in sectors like cosmetics, personal care products, automotive, and research and development (R&D) services.

RESTRAIN:

Key hindrances to market growth include rising R&D expenses and fluctuations in packaging raw material costs.

Complex and strict regulations on hazardous material packaging and transportation present challenges for industry players, necessitating investment in compliant packaging designs and materials.

OPPORTUNITY:

Demand for safe packaging solutions is growing.

Driven by innovation, the packaging industry continuously advances solutions more efficient than traditional options. Demand for safe packing of expensive items has surged recently. Innovative bulk packaging, like intermediate bulk containers, ensures secure packaging of hazardous chemicals for various applications. Flexible containers aid in chemical transfer in powder form, while rigid ones handle liquid and granulated chemicals.

CHALLENGES:

The Inorganic Chemical Packaging market faces supply chain disruptions due to its reliance on materials sourced globally, vulnerable to geopolitical tensions and natural disasters.

Market challenges include intense competition among packaging providers, resulting in price wars and margin pressures.

The Russia-Ukraine crisis has reverberated across global industries, notably impacting the Inorganic Chemical Packaging Market in multifaceted ways. Supply chain disruptions have emerged as a key challenge, with both Russia and Ukraine serving as significant suppliers of raw materials integral to packaging production, including metals and petrochemicals. Sanctions on Russia and the regional conflict have disrupted these supplies, leading to shortages and escalating costs. Logistical challenges have further compounded the issue, affecting shipping routes through the Black Sea and Eastern Europe, thereby impeding the timely delivery of raw materials and finished goods.

The crisis has induced cost volatility within the market, driving up prices for packaging materials, particularly those reliant on petrochemicals and metals. Additionally, the surge in energy prices, particularly in Europe, has contributed to elevated production costs for these materials. Regulatory and market uncertainty have also taken center stage, as sanctions and trade restrictions between Western countries and Russia introduce ambiguity in trade routes and material availability. This uncertainty extends to market demand for inorganic chemicals and their packaging, as industries grapple with economic uncertainties and potential disruptions in the supply chain, influencing production decisions and timelines.

An economic slowdown significantly impacts the Inorganic Chemical Packaging Market, reducing demand due to decreased industrial activity and shifting consumer behavior. This leads to decreased production in key industries like manufacturing, construction, and automotive, resulting in deferred or canceled projects that typically require inorganic chemicals.

Operational challenges in the supply chain prompt cost-cutting measures as companies face tighter margins. While reduced congestion may improve logistics efficiency, heightened price sensitivity among consumers and businesses fosters a competitive environment where cost-effective packaging solutions are essential. As a result, companies may prioritize innovative packaging solutions to enhance value and performance, establishing differentiation in the market. The economic slowdown prompts market shifts, possibly driving consolidation as stronger companies acquire struggling counterparts, reshaping competition. Geographical variations in the downturn's impact may create new opportunities in less-affected regions.

By Packaging Format

Drums

Intermediate Bulk Containers

Flexitanks

Pails & Jerry Cans

Bags & Sacks

Others

The Intermediate Bulk Containers segment dominated the Inorganic Chemical Packaging market, holding approximately 22.5% of the market share. Manufacturers globally produce a diverse array of intermediate bulk containers, including both plastic and stainless steel rigid intermediate bulk containers. The most common type of intermediate bulk containers, ranging in capacity from 800 to 1,250 liters, comprises roughly half of all supplied intermediate bulk containers.

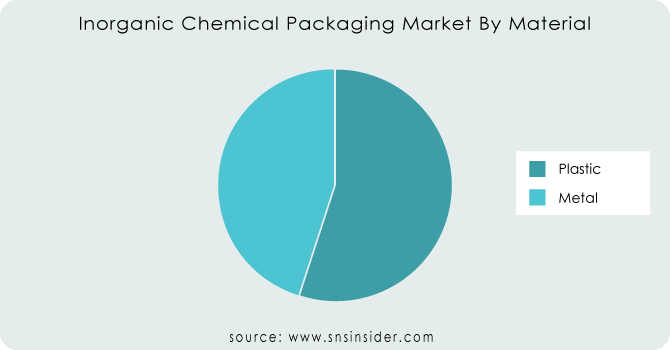

By Material

Metal

Plastic

The Plastic segment dominated the Inorganic Chemical Packaging market, holding approximately 58.8% of the market share. Plastic has emerged as the preferred material for industrial chemical packaging manufacturers, according to FMI. Recyclable plastics like high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), and polyvinyl chloride (PVC) are popular due to their strength and durability, essential for safe handling of industrial chemicals. Extensive research and development investments have led to the development of metallized polyethylene terephthalate (MET-PET), which is moisture-resistant and fully recyclable, making it ideal for transporting hazardous and valuable chemicals to remote areas.

Get Customized Report as per Your Business Requirement - Request For Customized Report

By Capacity

100-250 litres

250-500 litres

Over 500 Litres

By Application

Petrochemicals

Polymers

Consumer Chemicals

Speciality Chemicals

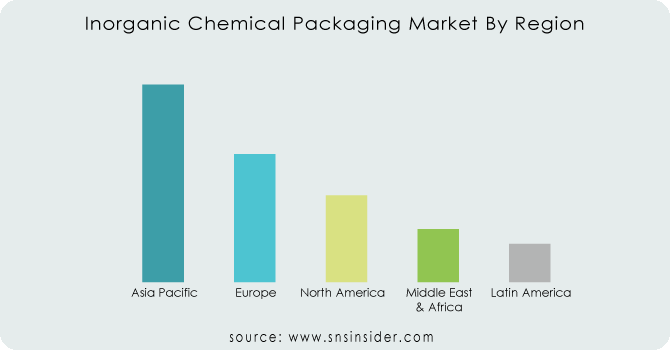

The Asia Pacific region dominated the Inorganic Chemical Packaging market, accounting for 42% of the market revenue. The Asia Pacific region observed a substantial share. Intermediate bulk containers (IBCs) and steel drums are regarded as secure packaging choices for such materials, thus it is predicted that the increasing occurrences of hazardous chemical storage and transportation would promote their usage. The market is expanding in the region due to health risks posed by chemical leaks and leaching, as well as the growing demand for solutions that minimize exposure to the external environment.

Europe is expected to witness significant growth during the projection. European regulatory bodies have implemented specific quantitative restrictions on the packaging of hazardous chemicals during domestic and international transit. Chemical manufacturers must comply with classification, labelling, and packaging (CLP) regulations aimed at ensuring the safe and efficient transport of hazardous products worldwide. North America is expected to be the fastest-growing region due to the strong presence of key market players and continuous technological advancements in packaging solutions, reflecting the region's dynamic market landscape and commitment to innovation. This positions it for significant growth in the evolving petrochemical packaging industry.

REGIONAL COVERAGE:

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

Some of the major players in the Inorganic Chemical Packaging Market are Berry Global, TPL Plastech, The Cary Company, Hoover Ferguson Group, Milford Barrel, International Paper, Orlando Drum & Container Corporation, DS Smith, Snyder Industries, Sealed Air and other players.

Berry Global-Company Financial Analysis

During April 2021, ProAmpac acquired IG Industries PLC and Brayford Plastics Ltd., both UK-based companies, with the objective of manufacturing recyclable packaging.

In October 2020, Myers Industries, Inc. acquired Elkhart Plastics, Inc., the fifth-largest rotational molder in the United States. As part of its long-term strategy to become a high-growth producer of engineered plastic solutions, this acquisition is viewed as a pivotal step towards realizing that goal.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 3.12 Billion |

| Market Size by 2031 | US$ 4.30 Billion |

| CAGR | CAGR of 4.1 % From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Packaging Format (Drums, Intermediate Bulk Containers, Flexitanks, Pails & Jerry Cans, Bags & Sacks, Others) • By Material (Metal, Plastic) • By Capacity (100-250 Litres, 250-500 Litres, Over 500 Litres) • By Application (Petrochemicals, Polymers, Consumer Chemicals, Speciality Chemicals) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Berry Global, TPL Plastech, The Cary Company, Hoover Ferguson Group, Milford Barrel, International Paper, Orlando Drum & Container Corporation, DS Smith, Snyder Industries, Sealed Air |

| Key Drivers | • The demand for shrink drum liners in the packaging of inorganic chemicals is on the rise. • Expansion of production capacities across different end-use sectors like food and beverages and chemical processing. |

| Restraints | • Key hindrances to market growth include rising R&D expenses and fluctuations in packaging raw material costs. • Complex and strict regulations on hazardous material packaging and transportation present challenges for industry players, necessitating investment in compliant packaging designs and materials. |

Ans: The Inorganic Chemical Packaging Market is expected to grow at a CAGR of 4.1%.

Ans: The Inorganic Chemical Packaging Market size was USD 3.12 billion in 2023 and is expected to Reach USD 4.30 billion by 2031.

Ans: Expansion of production capacities across different end-use sectors like food and beverages and chemical processing.

Ans: Key hindrances to market growth include rising R&D expenses and fluctuations in packaging raw material costs.

Ans: The Asia-Pacific region held the largest market share and will continue to dominate the market.

TABLE OF CONTENTS

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Industry Flowchart

3. Research Methodology

4. Market Dynamics

4.1 Drivers

4.2 Restraints

4.3 Opportunities

4.4 Challenges

5. Impact Analysis

5.1 Impact of Russia-Ukraine Crisis

5.2 Impact of Economic Slowdown on Major Countries

5.2.1 Introduction

5.2.2 United States

5.2.3 Canada

5.2.4 Germany

5.2.5 France

5.2.6 UK

5.2.7 China

5.2.8 Japan

5.2.9 South Korea

5.2.10 India

6. Value Chain Analysis

7. Porter’s 5 Forces Model

8. Pest Analysis

9. Inorganic Chemical Packaging Market Segmentation, By Packaging Format

9.1 Introduction

9.2 Trend Analysis

9.3 Drums

9.4 Intermediate Bulk Containers

9.5 Flexitanks

9.6 Pails & Jerry Cans

9.7 Bags & Sacks

9.8 Others

10. Inorganic Chemical Packaging Market Segmentation, By Material

10.1 Introduction

10.2 Trend Analysis

10.3 Metal

10.4 Plastic

11. Inorganic Chemical Packaging Market Segmentation, By Capacity

11.1 Introduction

11.2 Trend Analysis

11.3 100-250 litres

11.4 250-500 litres

11.5 Over 500 Litres

12. Inorganic Chemical Packaging Market Segmentation, By Application

12.1 Introduction

12.2 Trend Analysis

12.3 Petrochemicals

12.4 Polymers

12.5 Consumer Chemicals

12.6 Speciality Chemicals

13. Regional Analysis

13.1 Introduction

13.2 North America

13.2.1 Trend Analysis

13.2.2 North America Inorganic Chemical Packaging Market By Country

13.2.3 North America Inorganic Chemical Packaging Market By Packaging Format

13.2.4 North America Inorganic Chemical Packaging Market By Material

13.2.5 North America Inorganic Chemical Packaging Market By Capacity

13.2.6 North America Inorganic Chemical Packaging Market By Application

13.2.7 USA

13.2.7.1 USA Inorganic Chemical Packaging Market By Packaging Format

13.2.7.2 USA Inorganic Chemical Packaging Market By Material

13.2.7.3 USA Inorganic Chemical Packaging Market By Capacity

13.2.7.4 USA Inorganic Chemical Packaging Market By Application

13.2.8 Canada

13.2.8.1 Canada Inorganic Chemical Packaging Market By Packaging Format

13.2.8.2 Canada Inorganic Chemical Packaging Market By Material

13.2.8.3 Canada Inorganic Chemical Packaging Market By Capacity

13.2.8.4 Canada Inorganic Chemical Packaging Market By Application

13.2.9 Mexico

13.2.9.1 Mexico Inorganic Chemical Packaging Market By Packaging Format

13.2.9.2 Mexico Inorganic Chemical Packaging Market By Material

13.2.9.3 Mexico Inorganic Chemical Packaging Market By Capacity

13.2.9.4 Mexico Inorganic Chemical Packaging Market By Application

13.3 Europe

13.3.1 Trend Analysis

13.3.2 Eastern Europe

13.3.2.1 Eastern Europe Inorganic Chemical Packaging Market By Country

13.3.2.2 Eastern Europe Inorganic Chemical Packaging Market By Packaging Format

13.3.2.3 Eastern Europe Inorganic Chemical Packaging Market By Material

13.3.2.4 Eastern Europe Inorganic Chemical Packaging Market By Capacity

13.3.2.5 Eastern Europe Inorganic Chemical Packaging Market By Application

13.3.2.6 Poland

13.3.2.6.1 Poland Inorganic Chemical Packaging Market By Packaging Format

13.3.2.6.2 Poland Inorganic Chemical Packaging Market By Material

13.3.2.6.3 Poland Inorganic Chemical Packaging Market By Capacity

13.3.2.6.4 Poland Inorganic Chemical Packaging Market By Application

13.3.2.7 Romania

13.3.2.7.1 Romania Inorganic Chemical Packaging Market By Packaging Format

13.3.2.7.2 Romania Inorganic Chemical Packaging Market By Material

13.3.2.7.3 Romania Inorganic Chemical Packaging Market By Capacity

13.3.2.7.4 Romania Inorganic Chemical Packaging Market By Application

13.3.2.8 Hungary

13.3.2.8.1 Hungary Inorganic Chemical Packaging Market By Packaging Format

13.3.2.8.2 Hungary Inorganic Chemical Packaging Market By Material

13.3.2.8.3 Hungary Inorganic Chemical Packaging Market By Capacity

13.3.2.8.4 Hungary Inorganic Chemical Packaging Market By Application

13.3.2.9 Turkey

13.3.2.9.1 Turkey Inorganic Chemical Packaging Market By Packaging Format

13.3.2.9.2 Turkey Inorganic Chemical Packaging Market By Material

13.3.2.9.3 Turkey Inorganic Chemical Packaging Market By Capacity

13.3.2.9.4 Turkey Inorganic Chemical Packaging Market By Application

13.3.2.10 Rest of Eastern Europe

13.3.2.10.1 Rest of Eastern Europe Inorganic Chemical Packaging Market By Packaging Format

13.3.2.10.2 Rest of Eastern Europe Inorganic Chemical Packaging Market By Material

13.3.2.10.3 Rest of Eastern Europe Inorganic Chemical Packaging Market By Capacity

13.3.2.10.4 Rest of Eastern Europe Inorganic Chemical Packaging Market By Application

13.3.3 Western Europe

13.3.3.1 Western Europe Inorganic Chemical Packaging Market By Country

13.3.3.2 Western Europe Inorganic Chemical Packaging Market By Packaging Format

13.3.3.3 Western Europe Inorganic Chemical Packaging Market By Material

13.3.3.4 Western Europe Inorganic Chemical Packaging Market By Capacity

13.3.3.5 Western Europe Inorganic Chemical Packaging Market By Application

13.3.3.6 Germany

13.3.3.6.1 Germany Inorganic Chemical Packaging Market By Packaging Format

13.3.3.6.2 Germany Inorganic Chemical Packaging Market By Material

13.3.3.6.3 Germany Inorganic Chemical Packaging Market By Capacity

13.3.3.6.4 Germany Inorganic Chemical Packaging Market By Application

13.3.3.7 France

13.3.3.7.1 France Inorganic Chemical Packaging Market By Packaging Format

13.3.3.7.2 France Inorganic Chemical Packaging Market By Material

13.3.3.7.3 France Inorganic Chemical Packaging Market By Capacity

13.3.3.7.4 France Inorganic Chemical Packaging Market By Application

13.3.3.8 UK

13.3.3.8.1 UK Inorganic Chemical Packaging Market By Packaging Format

13.3.3.8.2 UK Inorganic Chemical Packaging Market By Material

13.3.3.8.3 UK Inorganic Chemical Packaging Market By Capacity

13.3.3.8.4 UK Inorganic Chemical Packaging Market By Application

13.3.3.9 Italy

13.3.3.9.1 Italy Inorganic Chemical Packaging Market By Packaging Format

13.3.3.9.2 Italy Inorganic Chemical Packaging Market By Material

13.3.3.9.3 Italy Inorganic Chemical Packaging Market By Capacity

13.3.3.9.4 Italy Inorganic Chemical Packaging Market By Application

13.3.3.10 Spain

13.3.3.10.1 Spain Inorganic Chemical Packaging Market By Packaging Format

13.3.3.10.2 Spain Inorganic Chemical Packaging Market By Material

13.3.3.10.3 Spain Inorganic Chemical Packaging Market By Capacity

13.3.3.10.4 Spain Inorganic Chemical Packaging Market By Application

13.3.3.11 Netherlands

13.3.3.11.1 Netherlands Inorganic Chemical Packaging Market By Packaging Format

13.3.3.11.2 Netherlands Inorganic Chemical Packaging Market By Material

13.3.3.11.3 Netherlands Inorganic Chemical Packaging Market By Capacity

13.3.3.11.4 Netherlands Inorganic Chemical Packaging Market By Application

13.3.3.12 Switzerland

13.3.3.12.1 Switzerland Inorganic Chemical Packaging Market By Packaging Format

13.3.3.12.2 Switzerland Inorganic Chemical Packaging Market By Material

13.3.3.12.3 Switzerland Inorganic Chemical Packaging Market By Capacity

13.3.3.12.4 Switzerland Inorganic Chemical Packaging Market By Application

13.3.3.13 Austria

13.3.3.13.1 Austria Inorganic Chemical Packaging Market By Packaging Format

13.3.3.13.2 Austria Inorganic Chemical Packaging Market By Material

13.3.3.13.3 Austria Inorganic Chemical Packaging Market By Capacity

13.3.3.13.4 Austria Inorganic Chemical Packaging Market By Application

13.3.3.14 Rest of Western Europe

13.3.3.14.1 Rest of Western Europe Inorganic Chemical Packaging Market By Packaging Format

13.3.3.14.2 Rest of Western Europe Inorganic Chemical Packaging Market By Material

13.3.3.14.3 Rest of Western Europe Inorganic Chemical Packaging Market By Capacity

13.3.3.14.4 Rest of Western Europe Inorganic Chemical Packaging Market By Application

13.4 Asia-Pacific

13.4.1 Trend Analysis

13.4.2 Asia-Pacific Inorganic Chemical Packaging Market By Country

13.4.3 Asia-Pacific Inorganic Chemical Packaging Market By Packaging Format

13.4.4 Asia-Pacific Inorganic Chemical Packaging Market By Material

13.4.5 Asia-Pacific Inorganic Chemical Packaging Market By Capacity

13.4.6 Asia-Pacific Inorganic Chemical Packaging Market By Application

13.4.7 China

13.4.7.1 China Inorganic Chemical Packaging Market By Packaging Format

13.4.7.2 China Inorganic Chemical Packaging Market By Material

13.4.7.3 China Inorganic Chemical Packaging Market By Capacity

13.4.7.4 China Inorganic Chemical Packaging Market By Application

13.4.8 India

13.4.8.1 India Inorganic Chemical Packaging Market By Packaging Format

13.4.8.2 India Inorganic Chemical Packaging Market By Material

13.4.8.3 India Inorganic Chemical Packaging Market By Capacity

13.4.8.4 India Inorganic Chemical Packaging Market By Application

13.4.9 Japan

13.4.9.1 Japan Inorganic Chemical Packaging Market By Packaging Format

13.4.9.2 Japan Inorganic Chemical Packaging Market By Material

13.4.9.3 Japan Inorganic Chemical Packaging Market By Capacity

13.4.9.4 Japan Inorganic Chemical Packaging Market By Application

13.4.10 South Korea

13.4.10.1 South Korea Inorganic Chemical Packaging Market By Packaging Format

13.4.10.2 South Korea Inorganic Chemical Packaging Market By Material

13.4.10.3 South Korea Inorganic Chemical Packaging Market By Capacity

13.4.10.4 South Korea Inorganic Chemical Packaging Market By Application

13.4.11 Vietnam

13.4.11.1 Vietnam Inorganic Chemical Packaging Market By Packaging Format

13.4.11.2 Vietnam Inorganic Chemical Packaging Market By Material

13.4.11.3 Vietnam Inorganic Chemical Packaging Market By Capacity

13.4.11.4 Vietnam Inorganic Chemical Packaging Market By Application

13.4.12 Singapore

13.4.12.1 Singapore Inorganic Chemical Packaging Market By Packaging Format

13.4.12.2 Singapore Inorganic Chemical Packaging Market By Material

13.4.12.3 Singapore Inorganic Chemical Packaging Market By Capacity

13.4.12.4 Singapore Inorganic Chemical Packaging Market By Application

13.4.13 Australia

13.4.13.1 Australia Inorganic Chemical Packaging Market By Packaging Format

13.4.13.2 Australia Inorganic Chemical Packaging Market By Material

13.4.13.3 Australia Inorganic Chemical Packaging Market By Capacity

13.4.13.4 Australia Inorganic Chemical Packaging Market By Application

13.4.14 Rest of Asia-Pacific

13.4.14.1 Rest of Asia-Pacific Inorganic Chemical Packaging Market By Packaging Format

13.4.14.2 Rest of Asia-Pacific Inorganic Chemical Packaging Market By Material

13.4.14.3 Rest of Asia-Pacific Inorganic Chemical Packaging Market By Capacity

13.4.14.4 Rest of Asia-Pacific Inorganic Chemical Packaging Market By Application

13.5 Middle East & Africa

13.5.1 Trend Analysis

13.5.2 Middle East

13.5.2.1 Middle East Inorganic Chemical Packaging Market By Country

13.5.2.2 Middle East Inorganic Chemical Packaging Market By Packaging Format

13.5.2.3 Middle East Inorganic Chemical Packaging Market By Material

13.5.2.4 Middle East Inorganic Chemical Packaging Market By Capacity

13.5.2.5 Middle East Inorganic Chemical Packaging Market By Application

13.5.2.6 UAE

13.5.2.6.1 UAE Inorganic Chemical Packaging Market By Packaging Format

13.5.2.6.2 UAE Inorganic Chemical Packaging Market By Material

13.5.2.6.3 UAE Inorganic Chemical Packaging Market By Capacity

13.5.2.6.4 UAE Inorganic Chemical Packaging Market By Application

13.5.2.7 Egypt

13.5.2.7.1 Egypt Inorganic Chemical Packaging Market By Packaging Format

13.5.2.7.2 Egypt Inorganic Chemical Packaging Market By Material

13.5.2.7.3 Egypt Inorganic Chemical Packaging Market By Capacity

13.5.2.7.4 Egypt Inorganic Chemical Packaging Market By Application

13.5.2.8 Saudi Arabia

13.5.2.8.1 Saudi Arabia Inorganic Chemical Packaging Market By Packaging Format

13.5.2.8.2 Saudi Arabia Inorganic Chemical Packaging Market By Material

13.5.2.8.3 Saudi Arabia Inorganic Chemical Packaging Market By Capacity

13.5.2.8.4 Saudi Arabia Inorganic Chemical Packaging Market By Application

13.5.2.9 Qatar

13.5.2.9.1 Qatar Inorganic Chemical Packaging Market By Packaging Format

13.5.2.9.2 Qatar Inorganic Chemical Packaging Market By Material

13.5.2.9.3 Qatar Inorganic Chemical Packaging Market By Capacity

13.5.2.9.4 Qatar Inorganic Chemical Packaging Market By Application

13.5.2.10 Rest of Middle East

13.5.2.10.1 Rest of Middle East Inorganic Chemical Packaging Market By Packaging Format

13.5.2.10.2 Rest of Middle East Inorganic Chemical Packaging Market By Material

13.5.2.10.3 Rest of Middle East Inorganic Chemical Packaging Market By Capacity

13.5.2.10.4 Rest of Middle East Inorganic Chemical Packaging Market By Application

13.5.3 Africa

13.5.3.1 Africa Inorganic Chemical Packaging Market By Country

13.5.3.2 Africa Inorganic Chemical Packaging Market By Packaging Format

13.5.3.3 Africa Inorganic Chemical Packaging Market By Material

13.5.3.4 Africa Inorganic Chemical Packaging Market By Capacity

13.5.3.5 Africa Inorganic Chemical Packaging Market By Application

13.5.3.6 Nigeria

13.5.3.6.1 Nigeria Inorganic Chemical Packaging Market By Packaging Format

13.5.3.6.2 Nigeria Inorganic Chemical Packaging Market By Material

13.5.3.6.3 Nigeria Inorganic Chemical Packaging Market By Capacity

13.5.3.6.4 Nigeria Inorganic Chemical Packaging Market By Application

13.5.3.7 South Africa

13.5.3.7.1 South Africa Inorganic Chemical Packaging Market By Packaging Format

13.5.3.7.2 South Africa Inorganic Chemical Packaging Market By Material

13.5.3.7.3 South Africa Inorganic Chemical Packaging Market By Capacity

13.5.3.7.4 South Africa Inorganic Chemical Packaging Market By Application

13.5.3.8 Rest of Africa

13.5.3.8.1 Rest of Africa Inorganic Chemical Packaging Market By Packaging Format

13.5.3.8.2 Rest of Africa Inorganic Chemical Packaging Market By Material

13.5.3.8.3 Rest of Africa Inorganic Chemical Packaging Market By Capacity

13.5.3.8.4 Rest of Africa Inorganic Chemical Packaging Market By Application

13.6 Latin America

13.6.1 Trend Analysis

13.6.2 Latin America Inorganic Chemical Packaging Market By country

13.6.3 Latin America Inorganic Chemical Packaging Market By Packaging Format

13.6.4 Latin America Inorganic Chemical Packaging Market By Material

13.6.5 Latin America Inorganic Chemical Packaging Market By Capacity

13.6.6 Latin America Inorganic Chemical Packaging Market By Application

13.6.7 Brazil

13.6.7.1 Brazil Inorganic Chemical Packaging Market By Packaging Format

13.6.7.2 Brazil Inorganic Chemical Packaging Market By Material

13.6.7.3 Brazil Inorganic Chemical Packaging Market By Capacity

13.6.7.4 Brazil Inorganic Chemical Packaging Market By Application

13.6.8 Argentina

13.6.8.1 Argentina Inorganic Chemical Packaging Market By Packaging Format

13.6.8.2 Argentina Inorganic Chemical Packaging Market By Material

13.6.8.3 Argentina Inorganic Chemical Packaging Market By Capacity

13.6.8.4 Argentina Inorganic Chemical Packaging Market By Application

13.6.9 Colombia

13.6.9.1 Colombia Inorganic Chemical Packaging Market By Packaging Format

13.6.9.2 Colombia Inorganic Chemical Packaging Market By Material

13.6.9.3 Colombia Inorganic Chemical Packaging Market By Capacity

13.6.9.4 Colombia Inorganic Chemical Packaging Market By Application

13.6.10 Rest of Latin America

13.6.10.1 Rest of Latin America Inorganic Chemical Packaging Market By Packaging Format

13.6.10.2 Rest of Latin America Inorganic Chemical Packaging Market By Material

13.6.10.3 Rest of Latin America Inorganic Chemical Packaging Market By Capacity

13.6.10.4 Rest of Latin America Inorganic Chemical Packaging Market By Application

14. Company Profiles

14.1 Berry Global

14.1.1 Company Overview

14.1.2 Financial

14.1.3 Products/ Services Offered

14.1.4 SWOT Analysis

14.1.5 The SNS View

14.2 TPL Plastech

14.2.1 Company Overview

14.2.2 Financial

14.2.3 Products/ Services Offered

14.2.4 SWOT Analysis

14.2.5 The SNS View

14.3 The Cary Company

14.3.1 Company Overview

14.3.2 Financial

14.3.3 Products/ Services Offered

14.3.4 SWOT Analysis

14.3.5 The SNS View

14.4 Hoover Ferguson Group

14.4.1 Company Overview

14.4.2 Financial

14.4.3 Products/ Services Offered

14.4.4 SWOT Analysis

14.4.5 The SNS View

14.5 Milford Barrel

14.5.1 Company Overview

14.5.2 Financial

14.5.3 Products/ Services Offered

14.5.4 SWOT Analysis

14.5.5 The SNS View

14.6 International Paper

14.6.1 Company Overview

14.6.2 Financial

14.6.3 Products/ Services Offered

14.6.4 SWOT Analysis

14.6.5 The SNS View

14.7 , Orlando Drum & Container Corporation

14.7.1 Company Overview

14.7.2 Financial

14.7.3 Products/ Services Offered

14.7.4 SWOT Analysis

14.7.5 The SNS View

14.8 DS Smith

14.8.1 Company Overview

14.8.2 Financial

14.8.3 Products/ Services Offered

14.8.4 SWOT Analysis

14.8.5 The SNS View

14.9 Snyder Industries

14.9.1 Company Overview

14.9.2 Financial

14.9.3 Products/ Services Offered

14.9.4 SWOT Analysis

14.9.5 The SNS View

14.10 Sealed Air

14.10.1 Company Overview

14.10.2 Financial

14.10.3 Products/ Services Offered

14.10.4 SWOT Analysis

14.10.5 The SNS View

15. Competitive Landscape

15.1 Competitive Benchmarking

15.2 Market Share Analysis

15.3 Recent Developments

15.3.1 Industry News

15.3.2 Company News

15.3.3 Mergers & Acquisitions

16. Use Case and Best Practices

17. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

The Thermoformed Healthcare Packaging Market Size was valued at $48.41 billion in 2023 & will reach $94.53 billion by 2032 growing at a CAGR of 7.72% from 2024-2032

Battery Packaging Market Size was valued at USD 31.96 Billion in 2023 and is expected to reach USD 84.83 Billion by 2032 and grow at a CAGR of 11.57% over the forecast period 2024-2032.

The Packaging Solution Market Size was valued at USD 1184.3 billion in 2023 and is projected to reach USD 1845.13 billion by 2032 growing at a CAGR of 5.05% from 2024 to 2032.

The market size of In-Mold Labels market was US $ 3.75 billion in 2023 and is set to reach US $5.54 billion by 2031, at a compound annual growth rate of 4.91 % over the forecast period between 2024 and 2031.

The Molded Pulp Packaging Market size was valued at USD 6.02 billion in 2023 and is expected to reach USD 10.97 billion by 2032, registering a CAGR of 6.9% over the forecast period 2024-2032.

The Folding Carton Packaging Market size was valued at USD 167.01 billion in 2023 and is expected to increase to USD 239.33 billion in 2031, growing at a compound annual growth rate of 4.6% Over the Forecast Period of 2024-2031.

Hi! Click one of our member below to chat on Phone