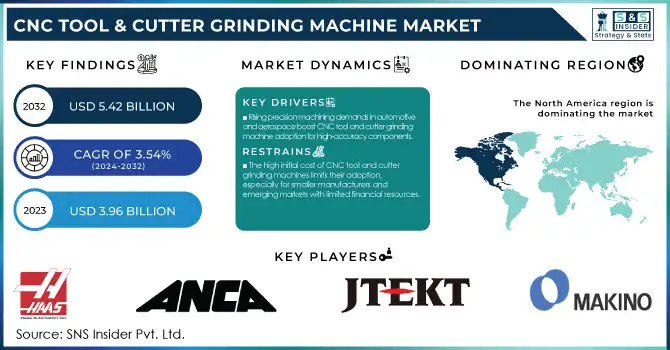

The CNC Tool & Cutter Grinding Machine Market size was valued at USD 3.96 Billion in 2023 and is expected to reach USD 5.42 Billion by 2032 With a growing CAGR of 3.54%. over the forecast period 2024-2032.

To get more information on CNC Tool & Cutter Grinding Machine Market - Request Free Sample Report

The CNC Tool & Cutter Grinding Machine Market report offers a comprehensive analysis of regional manufacturing output trends and utilization rates, along with an in-depth look at maintenance and downtime metrics It illustrates the adoption of advanced technologies across multiple regions and a comparative overview of the regional export/import dynamic. Such data have significant implications for market efficiency, technology dependency, and competition by geography, among others.

DRIVERS

The rising demand for precision machining, driven by industries like automotive and aerospace, fuels the growth of CNC tool and cutter grinding machines for high-accuracy, tight-tolerance components.

The rising demand for precision machining is a key growth driver for the CNC tool and cutter grinding machine market. Industries such as automotive, aerospace, and defense are becoming more dependent on high-fidelity components that require tight tolerances and flawless finishes. The grinding of the tool and cutter is performed by the CNC tool and cutter grinding machine, which produce drilling milling and grinding tools with better accuracy, repeatability, and efficiency. The increasing demand for these machines is also driven by recent technological developments in the manufacturing process, including the requirement for custom-made and high-grade instruments. This growth is also driven by other trends such as a shift towards lightweight materials in aerospace and automotive industries and increased adoption of electric vehicles. These advancements in CNC grinding technologies, like automation and smart functions, enhance productivity and precision, which in turn only serves to strengthen the critical role that these machines play in a multitude of industries This trend will continue as global manufacturing needs change.

RESTRAINT

The high initial cost of CNC tool and cutter grinding machines limits their adoption, especially for smaller manufacturers and emerging markets with limited financial resources.

The high initial cost of CNC tool and cutter grinding machines is a significant barrier, particularly for smaller manufacturers or businesses in emerging markets. The machines involve a large amount of capital investment, such as advanced model purchasing, installation, and operator training. They are expensive to acquire, with many of the advanced models costing millions of dollars, not to mention that a significant amount of money must be put into install and operator training. This results in many SMEs having to forego advanced manufacturing technologies because they cannot afford to pay for the individual capital investments upfront. In addition, the complexity of these devices makes them more expensive, causing companies with shallow wallets to find it hard to justify the spending. For example, in some countries the high cost of the product hinders the adoption of CNC grinders, especially where price sensitivity is greater or if manufacturing companies are reluctant to spend on high-end product lines without any guaranteed returns.

OPPORTUNITY

The growth of 3D printing in industries like aerospace creates opportunities for CNC tool and cutter grinding machines to refine 3D printed components through post-processing, ensuring precision and quality.

The expansion of 3D printing and additive manufacturing, particularly in industries like aerospace, is creating new opportunities for CNC tool and cutter grinding machines. While additive manufacturing enables production of complex and customized parts that are built layer by layer, many additive manufacturing components need post-processing to meet the target surface finish, accuracy, and functionality. Machine tools are critical to this process, including CNC tool and cutter grinding machines which can shape and sharpen tools used in 3D printing or perhaps polish the final components to meet stringent industry standards. In the case of aerospace, where performance and safety are paramount, CNC grinding of 3D printed parts removes defects and achieves surface finish specifications. The integration of these technologies leads to improved production processes and expanding design choices, ultimately resulting in superior-quality final products.

CHALLENGES

Stricter environmental regulations on waste disposal, energy use, and emissions impose additional costs and challenges for CNC tool and cutter grinding machine manufacturers.

Environmental regulations have become more stringent across various industries, and the CNC tool and cutter grinding machine market is no exception. Manufacturers now have to adhere to regulations on waste disposal, energy consumption, and carbon emissions. For example, these rules can require using environmentally friendly materials, practices that save energy, and the disposal of industrial waste such as metal shavings, oils, and other environmental pollutants. CNC machine manufacturers have to spend on advanced production technologies that'll minimize waste generation, along with waste management systems and machines that consume less energy, ultimately leading to a rise in operational costs. Moreover, this process may also entail periodic audits and certifications by environmental compliance organizations, as well as the potential to up to upgrade equipment, which will only serve to raise costs even further. As much as these regulations encourage sustainable practices, they create hurdles for manufacturers, specifically small-scale firms with fewer resources. Indeed, the shifting dynamics here could prove daunting for many, yet those that adjust to these demands may find themselves ahead of the game by catering to environmentally aware consumers and businesses alike.

By Type

The Universal Grinding Machines segment dominated with a market share of over 48% in 2023, due to their flexibility and versatility. These machines can handle a wide range of applications, making them highly sought after across industries such as automotive, aerospace, and manufacturing. They can also serve varied production requirements because of their aptitude for grinding several kinds of tools, even complex geometries. Universal grinders vary from other specific machines due to their flexibility since they can be used for different types of materials and cutting tools. This flexibility also eliminates the need of multiple machines, thus making them economical to manufacturers. Universal grinding machines have not lost any visibility in the market, with various industries looking for solutions that offer improved productivity and precision consequently leading to their dominance in the sector.

By Application

The Automotive segment dominated with a market share of over 44% in 2023, due to the growing demand for precision manufacturing and tooling in automotive production. The invention of new components in vehicles brings ever-increasing quality, accuracy, efficiency and durability requirements for tools. The best example of the required precision apart from engine components is gears and transmission system, where CNC grinding machine plays a vital role in producing them. The stringent requirements set by the automotive industry in terms of better performance, improved safety, and greater fuel efficiency have led to a high demand for finely engineered, quality components which tends to increase the demand for tool grinding machines with CNC features. Furthermore, the emergence of electric vehicles and autonomous technologies is upping the complexity of automotive parts, maintaining demand in this segment.

North America region dominated with a market share over 38% in 2023, due to several key factors. The region hosts some of the global leading manufacturers of CNC machinery which leads to innovation and quality across the sector. Moreover, the growing acceptance of advanced technologies in North America strengthens the need for high-precision tools needed by manufacturing sectors like automotive, aerospace, and precision engineering. CNC machines are widely used in these industries, allowing market growth in demand for such machines. North America also dominates the global CNC Tool and Cutter grinding machine market due to the presence of well-established manufacturing hubs in the U.S. and Canada, and significant research and development investments.

Asia-Pacific is the fastest-growing region in the CNC Tool & Cutter Grinding Machine market, primarily due to rapid industrialization and a burgeoning manufacturing sector across countries like China, Japan, and India. These countries are progressively concentrating on improving their manufacturing competence, resulting in a rising requirement for high-precision tooling to cater to sectors such as automotive, aerospace, and electronics. This is furtherly boosted by the advent of automation and smart manufacturing, which upgrades production efficiency and minimize the cost of operations. The increasing adoption of Industry 4.0, robotics, and IoT in manufacturing plants are other factors aiding in the growth of sophisticated CNC tool and cutter grinding machines, and consequently, the fast market growth in the region.

Need any customization research on CNC Tool & Cutter Grinding Machine Market - Enquiry Now

Some of the major key players of the CNC Tool & Cutter Grinding Machine Market

Vollmer (CNC Tool Grinding Machines, CNC Tool Grinders)

Makino Milling Machine Co. (CNC Milling Machines, CNC Tool Grinders)

Haas Automation, Inc.(CNC Vertical and Horizontal Machining Centers)

ANCA Pty Ltd. (CNC Tool and Cutter Grinders)

ISOG Technology GmbH (CNC Grinding Machines, Tool Grinding Systems)

JTEKT Corp (CNC Tool Grinding Machines, Grinding Machine Components)

Korber AG (CNC Tool Grinding Machines, Grinding Systems)

Amada Machine Tools Co.(CNC Grinding Machines, Surface Grinders)

DANOBAT Group (CNC Grinding Machines, Tool Grinding Solutions)

WIDMA Machine Tools (CNC Tool Grinders, CNC Grinding Machines)

Rollomatic SA (CNC Tool Grinding Machines, Grinding Centers)

J Schneeberger Maschinen AG (CNC Grinding Machines, Tool Grinders)

Gleason Corporation (CNC Gear Grinding Machines, Tool Grinders)

Gebr. SAACKE GmbH & Co. KG (CNC Tool Grinding Machines, Grinding Tools)

Alfred H. Schütte GmbH & Co. KG (CNC Tool Grinding Machines, Precision Grinders)

JUNKER Group (CNC Grinding Machines, Tool Grinding Systems)

United Grinding Group (CNC Tool Grinding Machines, Surface Grinders)

Mitsubishi Heavy Industries Machine Tool Co., Ltd. (CNC Tool Grinders, Surface Grinding Machines)

KUKA Robotics (CNC Grinding Systems, Industrial Robots for Grinding)

Fives Group (CNC Grinding Machines, Tool Grinding Solutions)

Suppliers for (highly accurate, precise grinding machines used for sharpening and manufacturing cutting tools, which are critical in industries like aerospace, automotive, and metalworking) on CNC Tool & Cutter Grinding Machine Market

Vollmer

Makino Milling Machine Co., Ltd.

Haas Automation, Inc.

ANCA Pty Ltd.

ISOG Technology GmbH

JTEKT Corporation

Körber AG

Amada Machine Tools Co., Ltd.

DANOBAT Group

WIDMA Machine Tools

RECENT DEVELOPMENT

In June 24, 2024: Kuka Robotics showcased its latest automation solutions at IMTS 2024, including automated milling and metal additive manufacturing systems, designed to streamline part processing and boost production efficiency. Notably, the CyberDrawers machine feeding unit from Waybo offers quick setup, with installation completed in just one day.

| Report Attributes | Details |

| Market Size in 2023 | USD 3.96 Billion |

| Market Size by 2032 | USD 5.42 Billion |

| CAGR | CAGR of 3.54% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Tool & Cutter Grinding Machine, Universal Grinding Machine, Blank and Cylindrical Grinding Machines) • By Application (Electrical and Electronics Manufacturing, Aerospace & Defense, Automotive) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Vollmer, Makino Milling Machine Co., Ltd., Haas Automation, Inc., ANCA Pty Ltd., ISOG Technology GmbH, JTEKT Corp., Korber AG, Amada Machine Tools Co., Ltd., DANOBAT Group, WIDMA Machine Tools, Rollomatic SA, J Schneeberger Maschinen AG, Gleason Corporation, Gebr. SAACKE GmbH & Co. KG, Alfred H. Schütte GmbH & Co. KG, JUNKER Group, United Grinding Group, Mitsubishi Heavy Industries Machine Tool Co., Ltd., KUKA Robotics, Fives Group. |

Ans: The CNC Tool & Cutter Grinding Machine Market is expected to grow at a CAGR of 3.54% during 2024-2032.

Ans: The CNC Tool & Cutter Grinding Machine Market was USD 3.96 billion in 2023 and is expected to Reach USD 5.42 billion by 2032.

Ans: The rising demand for precision machining, driven by industries like automotive and aerospace, fuels the growth of CNC tool and cutter grinding machines for high-accuracy, tight-tolerance components.

Ans: The “Universal Grinding Machines” segment dominated the CNC Tool & Cutter Grinding Machine Market.

Ans: North America dominated the CNC Tool & Cutter Grinding Machine Market in 2023

Table of Contents:

1. Introduction

1.1 Market Definition

1.2 Scope (Inclusion and Exclusions)

1.3 Research Assumptions

2. Executive Summary

2.1 Market Overview

2.2 Regional Synopsis

2.3 Competitive Summary

3. Research Methodology

3.1 Top-Down Approach

3.2 Bottom-up Approach

3.3. Data Validation

3.4 Primary Interviews

4. Market Dynamics Impact Analysis

4.1 Market Driving Factors Analysis

4.1.2 Drivers

4.1.2 Restraints

4.1.3 Opportunities

4.1.4 Challenges

4.2 PESTLE Analysis

4.3 Porter’s Five Forces Model

5. Statistical Insights and Trends Reporting

5.1 Manufacturing Output, by Region (2020-2023)

5.2 Utilization Rates, by Region (2020-2023)

5.3 Maintenance and Downtime Metrics

5.4 Technological Adoption Rates, by Region

5.5 Export/Import Data, by Region (2023)

6. Competitive Landscape

6.1 List of Major Companies, By Region

6.2 Market Share Analysis, By Region

6.3 Product Benchmarking

6.3.1 Product specifications and features

6.3.2 Pricing

6.4 Strategic Initiatives

6.4.1 Marketing and promotional activities

6.4.2 Distribution and supply chain strategies

6.4.3 Expansion plans and new product launches

6.4.4 Strategic partnerships and collaborations

6.5 Technological Advancements

6.6 Market Positioning and Branding

7. CNC Tool & Cutter Grinding Machine Market Segmentation, By Type

7.1 Chapter Overview

7.2 Tool & Cutter Grinding Machine

7.2.1 Tool & Cutter Grinding Machine Market Trends Analysis (2020-2032)

7.2.2 Tool & Cutter Grinding Machine Market Size Estimates and Forecasts to 2032 (USD Billion)

7.3 Universal Grinding Machine

7.3.1 Universal Grinding Machine Market Trends Analysis (2020-2032)

7.3.2 Universal Grinding Machine Market Size Estimates and Forecasts to 2032 (USD Billion)

7.4 Blank and Cylindrical Grinding Machines

7.4.1 Blank and Cylindrical Grinding Machines Market Trends Analysis (2020-2032)

7.4.2 Blank and Cylindrical Grinding Machines Market Size Estimates and Forecasts to 2032 (USD Billion)

8. CNC Tool & Cutter Grinding Machine Market Segmentation, By Application

8.1 Chapter Overview

8.2 Electrical and Electronics Manufacturing

8.2.1 Electrical and Electronics Manufacturing Market Trends Analysis (2020-2032)

8.2.2 Electrical and Electronics Manufacturing Market Size Estimates and Forecasts to 2032 (USD Billion)

8.3 Aerospace & Defense

8.3.1 Aerospace & Defense Market Trends Analysis (2020-2032)

8.3.2 Aerospace & Defense Market Size Estimates and Forecasts to 2032 (USD Billion)

8.4 Automotive

8.4.1 Automotive Market Trends Analysis (2020-2032)

8.4.2 Automotive Market Size Estimates and Forecasts to 2032 (USD Billion)

9. Regional Analysis

9.1 Chapter Overview

9.2 North America

9.2.1 Trends Analysis

9.2.2 North America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.2.3 North America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.2.4 North America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.2.5 USA

9.2.5.1 USA CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.2.5.2 USA CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.2.6 Canada

9.2.6.1 Canada CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.2.6.2 Canada CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.2.7 Mexico

9.2.7.1 Mexico CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.2.7.2 Mexico CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3 Europe

9.3.1 Eastern Europe

9.3.1.1 Trends Analysis

9.3.1.2 Eastern Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.3.1.3 Eastern Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.4 Eastern Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.1.5 Poland

9.3.1.5.1 Poland CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.5.2 Poland CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.1.6 Romania

9.3.1.6.1 Romania CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.6.2 Romania CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.1.7 Hungary

9.3.1.7.1 Hungary CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.7.2 Hungary CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.1.8 Turkey

9.3.1.8.1 Turkey CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.8.2 Turkey CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.1.9 Rest of Eastern Europe

9.3.1.9.1 Rest of Eastern Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.1.9.2 Rest of Eastern Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2 Western Europe

9.3.2.1 Trends Analysis

9.3.2.2 Western Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.3.2.3 Western Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.4 Western Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.5 Germany

9.3.2.5.1 Germany CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.5.2 Germany CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.6 France

9.3.2.6.1 France CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.6.2 France CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.7 UK

9.3.2.7.1 UK CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.7.2 UK CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.8 Italy

9.3.2.8.1 Italy CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.8.2 Italy CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.9 Spain

9.3.2.9.1 Spain CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.9.2 Spain CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.10 Netherlands

9.3.2.10.1 Netherlands CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.10.2 Netherlands CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.11 Switzerland

9.3.2.11.1 Switzerland CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.11.2 Switzerland CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.12 Austria

9.3.2.12.1 Austria CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.12.2 Austria CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.3.2.13 Rest of Western Europe

9.3.2.13.1 Rest of Western Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.3.2.13.2 Rest of Western Europe CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4 Asia-Pacific

9.4.1 Trends Analysis

9.4.2 Asia-Pacific CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.4.3 Asia-Pacific CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.4 Asia-Pacific CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.5 China

9.4.5.1 China CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.5.2 China CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.6 India

9.4.5.1 India CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.5.2 India CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.5 Japan

9.4.5.1 Japan CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.5.2 Japan CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.6 South Korea

9.4.6.1 South Korea CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.6.2 South Korea CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.7 Vietnam

9.4.7.1 Vietnam CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.2.7.2 Vietnam CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.8 Singapore

9.4.8.1 Singapore CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.8.2 Singapore CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.9 Australia

9.4.9.1 Australia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.9.2 Australia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.4.10 Rest of Asia-Pacific

9.4.10.1 Rest of Asia-Pacific CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.4.10.2 Rest of Asia-Pacific CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5 Middle East and Africa

9.5.1 Middle East

9.5.1.1 Trends Analysis

9.5.1.2 Middle East CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.5.1.3 Middle East CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.4 Middle East CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.1.5 UAE

9.5.1.5.1 UAE CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.5.2 UAE CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.1.6 Egypt

9.5.1.6.1 Egypt CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.6.2 Egypt CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.1.7 Saudi Arabia

9.5.1.7.1 Saudi Arabia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.7.2 Saudi Arabia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.1.8 Qatar

9.5.1.8.1 Qatar CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.8.2 Qatar CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.1.9 Rest of Middle East

9.5.1.9.1 Rest of Middle East CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.1.9.2 Rest of Middle East CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.2 Africa

9.5.2.1 Trends Analysis

9.5.2.2 Africa CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.5.2.3 Africa CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.2.4 Africa CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.2.5 South Africa

9.5.2.5.1 South Africa CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.2.5.2 South Africa CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.5.2.6 Nigeria

9.5.2.6.1 Nigeria CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.5.2.6.2 Nigeria CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.6 Latin America

9.6.1 Trends Analysis

9.6.2 Latin America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

9.6.3 Latin America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.6.4 Latin America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.6.5 Brazil

9.6.5.1 Brazil CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.6.5.2 Brazil CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.6.6 Argentina

9.6.6.1 Argentina CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.6.6.2 Argentina CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.6.7 Colombia

9.6.7.1 Colombia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.6.7.2 Colombia CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

9.6.8 Rest of Latin America

9.6.8.1 Rest of Latin America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Type (2020-2032) (USD Billion)

9.6.8.2 Rest of Latin America CNC Tool & Cutter Grinding Machine Market Estimates and Forecasts, By Application (2020-2032) (USD Billion)

11. Company Profiles

11.1 Vollmer

11.1.1 Company Overview

11.1.2 Financial

11.1.3 Products/ Services Offered

11.1.4 SWOT Analysis

11.2 Makino Milling Machine Co., Ltd.

11.2.1 Company Overview

11.2.2 Financial

11.2.3 Products/ Services Offered

11.2.4 SWOT Analysis

11.3 Haas Automation, Inc.

11.3.1 Company Overview

11.3.2 Financial

11.3.3 Products/ Services Offered

11.3.4 SWOT Analysis

11.4 ANCA Pty Ltd.

11.4.1 Company Overview

11.4.2 Financial

11.4.3 Products/ Services Offered

11.4.4 SWOT Analysis

11.5 ISOG Technology GmbH

11.5.1 Company Overview

11.5.2 Financial

11.5.3 Products/ Services Offered

11.5.4 SWOT Analysis

11.6 JTEKT Corp

11.6.1 Company Overview

11.6.2 Financial

11.6.3 Products/ Services Offered

11.6.4 SWOT Analysis

11.7 Korber AG

11.7.1 Company Overview

11.7.2 Financial

11.7.3 Products/ Services Offered

11.7.4 SWOT Analysis

11.8 Amada Machine Tools Co., Ltd.

11.8.1 Company Overview

11.8.2 Financial

11.8.3 Products/ Services Offered

11.8.4 SWOT Analysis

11.9 DANOBAT Group

11.9.1 Company Overview

11.9.2 Financial

11.9.3 Products/ Services Offered

11.9.4 SWOT Analysis

11.10 WIDMA Machine Tools

11.10.1 Company Overview

11.10.2 Financial

11.10.3 Products/ Services Offered

11.10.4 SWOT Analysis

12. Use Cases and Best Practices

13. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

By Type

Tool & Cutter Grinding Machine

Universal Grinding Machine

Blank and Cylindrical Grinding Machines

By Application

Electrical and Electronics Manufacturing

Aerospace & Defense

Automotive

Request for Segment Customization as per your Business Requirement: Segment Customization Request

Regional Coverage:

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

Request for Country Level Research Report: Country Level Customization Request

Available Customization

With the given market data, SNS Insider offers customization as per the company’s specific needs. The following customization options are available for the report:

Detailed Volume Analysis

Criss-Cross segment analysis (e.g. Product X Application)

Competitive Product Benchmarking

Geographic Analysis

Additional countries in any of the regions

Customized Data Representation

Detailed analysis and profiling of additional market players

The Boring Tools Market Size was valued at USD 3.39 Billion in 2023 and is expected to reach USD 5.19 Billion by 2032 and grow at a CAGR of 4.73% over the forecast period 2024-2032.

The Laboratory Centrifuges Market Size was USD 1.76 Billion in 2023 and is expected to reach $2.65 Bn by 2032 and grow at a CAGR of 4.64% by 2024-2032.

The Food Packaging Equipment Market Size was estimated at USD 20.17 billion in 2023 and is expected to arrive at USD 29.82 billion by 2032 with a growing CAGR of 4.44% over the forecast period 2024-2032.

Bubble Generator Market was estimated at USD 1.31 Bn in 2023 and is expected to arrive at USD 2.34 Bn by 2032 with a growing CAGR of 6.64% from 2024-2032.

The Postal Automation Systems Market size was USD 0.76 Billion in 2023 and will reach to USD 1.38 Billion by 2032 and grow at a CAGR of 6.9% by 2024-2032.

Air conditioning System Market was valued at USD 116.50 Bn in 2023 and is anticipated to touch to USD 285.65 Bn by 2032, at a CAGR of 10.50% by 2024-2032.

Hi! Click one of our member below to chat on Phone