To get more information on CNC Milling Machine Tools Market - Request Free Sample Report

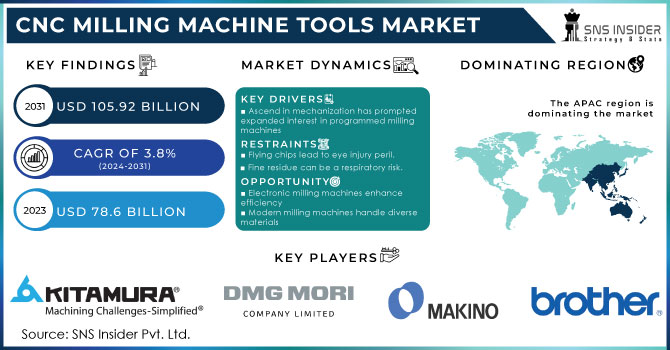

The CNC Milling Machine Tools Market size was valued at USD 78.6 billion in 2023 and is expected to reach USD 105.92 billion by 2031 and grow at a CAGR of 3.8% over the forecast period 2024-2031.

Milling is a method of eliminating unreasonable or undesirable material from any metal or different items utilizing a rotating shaper to give it an ideal shape and size. This is finished utilizing it is either physically controlled or programmed or both to CNC milling machine tools which. The significant-end clients of CNC milling machines incorporate cars, aviation, electrical and hardware, and others. The car area represents the most elevated share in the worldwide PC mathematical control milling machines market among the end clients. It is very well may be because of the appeal for accuracy parts and different parts utilized in the car area. Besides, the worldwide car industry is a significant supporter of the world's economy and creates the most appeal for CNC milling machines. In 2020, the auto area represented more than 35% of the market.

Milling machines are intended for isolating material from a workpiece utilizing rotational cutters. These machines can penetrate, bore, and cut a variety of materials. This course of eliminating bits of the material in accordance with the apparatus pivot is known as milling, and subsequently, the machines utilized in the process are called milling machines. Milling machines are accessible in many sorts and are utilized across an assortment of ventures. Milling machines utilize round and hollow apparatuses, for example, mill and drill to eliminate material. Milling machines are fundamentally utilized on level surfaces however they can work for certain sporadic surfaces as well.

MARKET DYNAMICS:

KEY DRIVERS:

Interest in top-notch items is the main consideration answerable for the ascent popularity of milling machines.

Ascend in mechanization has prompted expanded interest in programmed milling machines.

These machines are capital escalated and require a less human contribution.

RESTRAINTS:

Flying chips lead to eye injury peril.

Fine residue can be a respiratory risk.

mills can likewise be extremely clear, introducing danger to hearing as well as muffling voices, telephones, and cautions.

Different perils incorporate injury from the swarf, contact with the shaper or any alternating pieces of the machine, or injury brought about by a wrecked device.

CHALLENGES:

More unequal or unique mathematical examples, CNC machining may battle where a skillful craftsman can take care of business.

CNC machining, on account of its mechanical nature, can work well inside the limits of the equipment.

OPPORTUNITY:

The ascent of electronic milling machines has enabled organizations, everything being equal, further develop proficiency and decrease waste.

As material pliability, milling machines will work with a subsidiary mixture of metals, plastics, and, astonishingly, composite materials, making the advanced methods more adaptable.

IMPACT OF COVID-19:

Coronavirus has unfavorably impacted the computer numerical control milling machines’ piece of the pie. The opposition is remarkable between the enormous players, and the critical business departments for sellers are North America, APAC, and Europe. The noticeable merchants in this market are Doosan, Fives, F-Zimmermann, Jtekt, and Makino. The market is gradually moving from being concentrated, with few merchants partaking in a more critical lump of the general offer, turning into a divided one with a few free sellers jumping in.

The business will observe huge M&A exchanges toward the finish of 2020 (Q4) or mid-2021 as edge pressure develops, and food for more modest sellers is supposed to summons. The sellers with openness to just a solitary application or item are inclined to confront difficulties concerning keeping a constant flow of requests streaming in. Likewise, the assembling capacities of merchants change across the range.

MARKET ESTIMATION:

Vertical and horizontal milling machines both perform generally similar activities, yet the creative interaction is unique. The two sorts enjoy benefits and detriments, and both are more qualified to tasks. Nonetheless, since vertical milling machines are less expensive than others, they are generally famously utilized across end clients. The 3-Axis type CNC milling machine is the most common hub type due to its low cost and straightforwardness to use. Nonetheless, there are constraints with this type of machine as it can't be better to use on a machine with complex math.

5-6 pivot CNC milling machine offers quick working, exact, and micromachining. It has a few capacities which are better than 3 or 4-pivot milling machines. These machines are significantly utilized for creating parts/parts like aviation items, oil, and gas machine parts, vehicle molds, clinical innovation, compositional door jambs, military-grade items, and others. Accordingly, factors like high accuracy, application in muddled activities, and improved efficiency are projected to drive interest for 6-pivot CNC milling machines.

By Product Type

Vertical CNC Milling Machines

Horizontal CNC Milling Machines

Universal CNC Milling Machines

By Axis Type

3 Axis

4 Axis

Others

By End-User

Automobile

Electrical & Electronics

Aerospace & Defense

Others

REGIONAL ANALYSIS

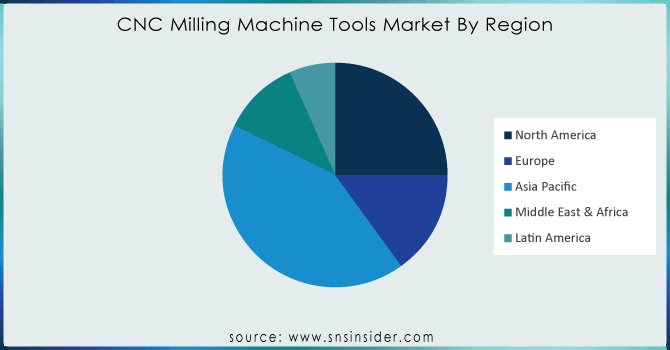

In 2021, APAC was the biggest income supporter of the worldwide CNC milling machine market, representing a portion of the overall industry of 46.49% in 2020. China represented a significant offer in the worldwide and provincial CNC CNC milling machine tools market. This can be ascribed to the rising number of interests in completely robotized modern hardware. Likewise, since the Chinese market has been fundamentally subject to its assembling enterprises, the interest for CNC is high in milling machines. Rising interests in the modern area and the consistent shift toward urbanization are significant full-scale factors moving the market during the estimated time frame. APAC ruled the market because of the expanded utilization of metal cutting techniques in the district.

Need any customization research on CNC Milling Machine Tools Market - Enquiry Now

REGIONAL COVERAGE:

North America

USA

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

The Netherlands

Rest of Europe

Asia-Pacific

Japan

south Korea

China

India

Australia

Rest of Asia-Pacific

The Middle East & Africa

Israel

UAE

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America

The Major Players are Brother Industries, Ltd., Dalian Machine Tool Group Corporation, DMG Mori Seiki Co. Ltd., GILDEMEISTER energy solutions GmbH, Kitamura Machinery, Makino Milling Machine Co., Ltd., Shenyang Machine Tools Co. Ltd. & Other Players

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 78.6 Billion |

| Market Size by 2031 | US$ 105.92 Billion |

| CAGR | CAGR of 3.8% From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Product type (Vertical CNC Milling Machines, Horizontal CNC Milling Machines, Universal CNC Milling Machines) • by axis type (3Axis,4 Axis, Others) • by end-use (Automobile, Electrical & Electronics, Aerospace & Defense) |

| Regional Analysis/Coverage | North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), The Middle East & Africa (Israel, UAE, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Brother Industries, Ltd., Dalian Machine Tool Group Corporation, DMG Mori Seiki Co. Ltd., GILDEMEISTER energy solutions GmbH, Kitamura Machinery, Makino Milling Machine Co., Ltd., Shenyang Machine Tools Co. Ltd. |

| Key Drivers | •Ascend in mechanization has prompted expanded interest in programmed milling machines. |

| Restraints | •Flying chips lead to eye injury peril. •Fine residue can be a respiratory risk. |

Ans: - The CNC Milling Machine Tools Market size was valued at USD 85.65 Bn in 2022.

Ans: - Flying chips lead to eye injury peril and fine residue can be a respiratory risk.

Ans: - China represented a significant offer in the worldwide and provincial CNC milling machine tools market.

Ans: - The primary growth tactics of CNC Milling Machine Tools market participants include merger and acquisition, business expansion, and product launch.

Ans: The CNC Milling Machine Tools Market is to grow at a CAGR of 5.71% From 2023 to 2030.

Table of Contents

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Research Methodology

3. Market Dynamics

3.1 Drivers

3.2 Restraints

3.3 Opportunities

3.4 Challenges

4. Impact Analysis

4.1 COVID-19 Impact Analysis

4.2 Impact of Ukraine- Russia War

4.3 Impact of Ongoing Recession

4.3.1 Introduction

4.3.2 Impact on major economies

4.3.2.1 US

4.3.2.2 Canada

4.3.2.3 Germany

4.3.2.4 France

4.3.2.5 United Kingdom

4.3.2.6 China

4.3.2.7 Japan

4.3.2.8 South Korea

4.3.2.9 Rest of the World

5. Value Chain Analysis

6. Porter’s 5 forces model

7. PEST Analysis

8. CNC Milling Machine Tools Market Segmentation, By Product

8.1 Vertical CNC Milling Machines

8.2 Horizontal CNC Milling Machines

8.3 Universal CNC Milling Machines

9. CNC Milling Machine Tools Market Segmentation, By Axis Type

9.1 Axis

9.2 Axis

9.3 Others

10. CNC Milling Machine Tools Market Segmentation, By End-use

10.1 Automobile

10.2 Electrical & Electronics

10.3 Aerospace & Defense

10.4 Others

11. Regional Analysis

11.1 Introduction

11.2 North America

11.2.1 USA

11.2.2 Canada

11.2.3 Mexico

11.3 Europe

11.3.1 Germany

11.3.2 UK

11.3.3 France

11.3.4 Italy

11.3.5 Spain

11.3.6 The Netherlands

11.3.7 Rest of Europe

11.4 Asia-Pacific

11.4.1 Japan

11.4.2 South Korea

11.4.3 China

11.4.4 India

11.4.5 Australia

11.4.6 Rest of Asia-Pacific

11.5 The Middle East & Africa

11.5.1 Israel

11.5.2 UAE

11.5.3 South Africa

11.5.4 Rest

11.6 Latin America

11.6.1 Brazil

11.6.2 Argentina

11.6.3 Rest of Latin America

12. Company Profiles

12.1 Brother Industries,

12.1.1 Financial

12.1.2 Products/ Services Offered

12.1.3 SWOT Analysis

12.1.4 The SNS view

12.2 Brother Industries, Ltd.

12.3 Dalian Machine Tool Group Corporation

12.4 DMG Mori Seiki Co. Ltd

12.5 GILDEMEISTER energy solutions GmbH

12.6 Kitamura Machinery

12.7 Makino Milling Machine Co.Ltd

12.8 Shenyang Machine Tools Co. Ltd.

13. Competitive Landscape

13.1 Competitive Benchmarking

13.2 Market Share Analysis

13.3 Recent Developments

14. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

The Residential Air Purifiers Market Size was estimated at USD 11.16 billion in 2023 and is expected to arrive at USD 23.24 billion by 2032 with a growing CAGR of 8.49% over the forecast period 2024-2032.

The Rotary Pumps Market size was valued at USD 7.85 Billion in 2023 and is now anticipated to grow to USD 11.26 Billion by 2032, displaying a compound annual growth rate (CAGR) of 3.68% during the forecast Period 2024-2032.

The High-speed Separator (HSS) Market Size was valued at USD 1.17 Billion in 2023 and is expected to reach USD 1.86 Billion by 2032 and grow at a CAGR of 5.30% over the forecast period 2024-2032.

The Optical Measurement Market size was estimated at USD 5.15 billion in 2023 and is expected to reach USD 9.38 billion by 2032 at a CAGR of 6.89% during the forecast period of 2024-2032.

The Industrial Valves Market Size will be valued at USD 83.55 billion by 2032 and it was valued at USD 125.68 billion in 2023, growing at a CAGR of 4.64% over the forecast period 2024-2032.

The Mooring Inspection Market was estimated at USD 412.70 Mn in 2023 and is expected to arrive at USD 549.45 Mn by 2032, at a CAGR of 3.23% from 2024-2032.

Hi! Click one of our member below to chat on Phone