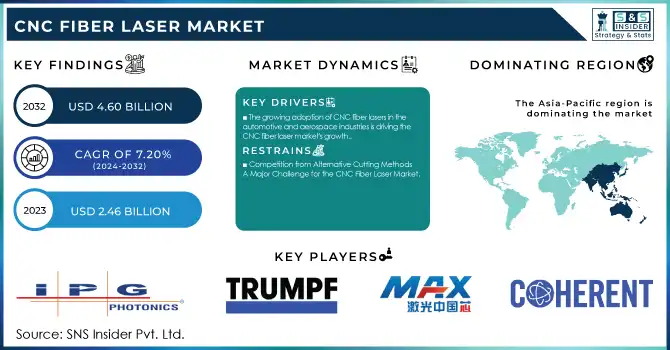

The CNC Fiber Laser Market Size was valued at USD 2.46 Billion in 2023 and is expected to grow to USD 4.60 Billion by 2032 and grow at a CAGR of 7.20% over the forecast period of 2024-2032.

To get more information on CNC Fiber Laser Market - Request Free Sample Report

The CNC Fiber Laser Market is witnessing robust growth, fueled by the widespread adoption of automation across key industries such as automotive, aerospace, and metalworking. As businesses increasingly embrace automated production lines, CNC fiber lasers are pivotal in enhancing productivity, reducing labor costs, and improving cutting precision. Industries are demanding high-speed, precise, and cost-effective laser cutting solutions, which has significantly boosted the demand for CNC fiber lasers. These systems are gaining popularity due to their ability to efficiently process a diverse range of materials, making them suitable for both mass production and custom manufacturing needs. Technological advancements in fiber laser technology are driving this demand further, with innovations that increase cutting speeds, accuracy, and energy efficiency, particularly when compared to traditional cutting methods. Industry reports indicate that CNC fiber lasers can improve production efficiency by 20-30% and cut energy consumption by up to 30% in automated environments. Additionally, these systems reduce human error and enhance operational efficiency by reducing manual intervention, making them ideal for high-volume production. As manufacturing practices shift towards sustainability, the demand for fiber lasers is further accelerating. Their low energy consumption and minimal waste generation make them a more environmentally friendly alternative to conventional cutting technologies. The competitive pricing of fiber laser cutting in regions such as China, where the cost can be as low as USD 15-20/hour, makes it a cost-effective option compared to the higher costs found in markets like the US and Europe. These advantages are driving global demand and positioning CNC fiber lasers as an essential tool in modern manufacturing, contributing significantly to the market's growth and reinforcing their role in future automated and sustainable production.

Drivers

The increasing adoption of CNC fiber lasers in the automotive and aerospace industries is significantly boosting the growth of the CNC fiber laser market.

These sectors require high-precision cutting and welding to manufacture essential components, and CNC fiber lasers have emerged as the preferred solution. In aerospace, CNC machining is transforming the production of complex parts by enhancing efficiency, reducing lead times, and ensuring the precise part geometry required to meet demanding performance standards. CNC fiber lasers are gaining traction in the automotive industry as well, where they are used for cutting metal sheets, tubes, and other components with high precision. This technology enables the production of lightweight, durable, and high-performance parts, offering design flexibility and the ability to use advanced materials like carbon fiber and aluminum alloys. The automotive sector has increasingly adopted CNC fiber lasers for cutting and welding applications, resulting in faster manufacturing speeds and improved precision. Laser welding in both industries provides high-quality joints with minimal heat distortion, improving overall strength and making it ideal for critical parts. Technological advancements in CNC fiber lasers, such as faster cutting speeds, better material compatibility, and enhanced energy efficiency, are further driving their adoption. For instance, laser additive manufacturing (AM) in aerospace eliminates the need for expensive tooling, such as sheet metal forming and friction stir welding fixtures, which can cost up to USD 2 million. This enables greater access to space and more flight opportunities. The widespread adoption of CNC fiber lasers in both automotive and aerospace sectors reflects their growing role in modern manufacturing, contributing to increased market demand and solidifying their place as a vital tool in industrial automation. These advancements and cost benefits are integral to the ongoing expansion of the CNC fiber laser market across these key industries.

Restraints

Competition from Alternative Cutting Methods - A Major Challenge for the CNC Fiber Laser Market

While CNC fiber lasers are known for their high precision, efficiency, and speed, alternatives still hold a strong position in the market, particularly due to their lower initial costs and suitability for specific applications. For instance, CO2 lasers are often preferred for cutting non-metallic materials, as they tend to be more cost-effective in such cases. Plasma cutting, on the other hand, remains a popular choice for cutting thicker metals, as it can offer lower operating costs despite sacrificing some precision. Additionally, water jet cutting is highly valued for its ability to cut through a wider range of materials, including thick and heat-sensitive materials, without generating heat-affected zones (HAZ), which is a common issue with laser cutting. While fiber lasers excel at high-speed and high-precision cuts, these other technologies remain relevant due to their versatility, lower operating costs, and ability to handle specific materials better. According to industry insights, plasma cutting can be as much as 40% cheaper for cutting thicker materials compared to fiber laser cutting, making it a preferred option in certain industries. Furthermore, water jet cutting has the advantage of no heat distortion, which is ideal for materials sensitive to temperature changes. Despite the superior energy efficiency of fiber lasers, which can reduce energy consumption by up to 30% compared to traditional CO2 lasers, the cost-effectiveness of competing technologies limits the widespread adoption of CNC fiber lasers, especially in applications where cost reduction is a priority. As a result, this competition continues to present a barrier to the market's growth, limiting fiber laser adoption in price-sensitive sectors.

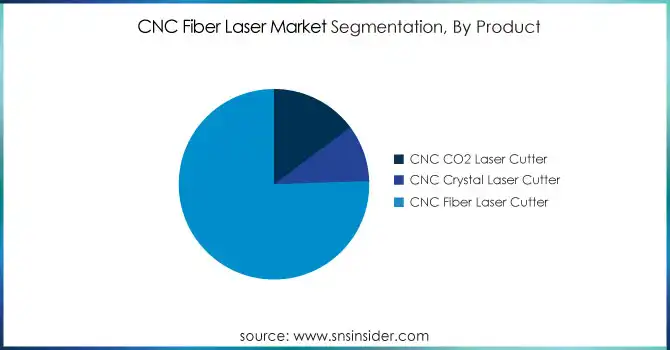

By Product

The CNC Fiber Laser Cutter segment is the dominant player in the CNC Fiber Laser market, accounting for approximately 76% of the market share in 2023. This dominance is attributed to the widespread adoption of fiber laser cutting technology due to its high precision, speed, and efficiency. CNC fiber laser cutters are ideal for industries such as automotive, aerospace, and metalworking, offering unparalleled accuracy for cutting a variety of materials, including metals, plastics, and composites. Their ability to cut intricate designs with minimal material waste makes them a preferred choice for manufacturers seeking cost-effective, high-quality production. As advancements in fiber laser technology continue to improve cutting speeds, energy efficiency, and material compatibility, the CNC Fiber Laser Cutter segment is expected to maintain its strong market presence in the coming years. This segment's growth is also driven by industrial automation and demand for sustainable manufacturing solutions.

By Type

The Stationary Gantry Type segment is leading the CNC Fiber Laser market, holding approximately 59% of the market share in 2023. This segment's dominance is driven by the high precision, stability, and versatility that stationary gantry systems offer, making them ideal for heavy-duty applications. These systems are widely used in industries such as aerospace, automotive, and metalworking, where accurate and efficient cutting of large and thick materials is crucial. The stationary gantry design, with its robust frame and precision control, ensures consistent cutting quality, even in high-volume production environments. The ability to handle complex tasks with minimal downtime has contributed to the popularity of this type of CNC fiber laser system. Additionally, advancements in technology, including increased cutting speeds and energy efficiency, further strengthen the segment’s market position.

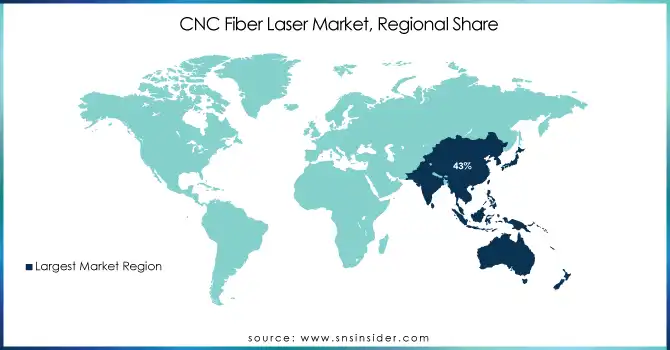

Asia-Pacific is the leading region in the CNC Fiber Laser market, holding a dominant share of around 43% in 2023. This growth is driven by the rapid industrialization, technological advancements, and increasing demand for automation in key countries like China, Japan, South Korea, and India. China, in particular, is the largest contributor, with a robust manufacturing sector and the adoption of advanced fiber laser technologies across industries such as automotive, aerospace, and electronics. Japan and South Korea are also significant players, driven by their high-tech industries and demand for precision in automotive and semiconductor manufacturing. Additionally, India is experiencing growth in CNC fiber laser adoption due to its expanding manufacturing and automotive sectors. The region's focus on enhancing production efficiency, reducing labor costs, and improving manufacturing capabilities has positioned Asia-Pacific as the leader in CNC fiber laser technologies. Moreover, the availability of cost-effective solutions and increased investments in automation have further fueled this region’s dominance in the market.

North America is the fastest-growing region in the CNC Fiber Laser market during the forecast period of 2024-2032, driven by the rapid industrial adoption of automation and advanced manufacturing technologies. The U.S. is a key player, with sectors like aerospace, automotive, and electronics fueling demand for high-precision cutting and welding solutions. The automotive industry, in particular, benefits from CNC fiber lasers for producing lightweight, high-performance parts, while the aerospace sector relies on these technologies for complex, precision components. Canada is also witnessing growth, especially in advanced manufacturing for sectors such as automotive, energy, and defense. Moreover, the region’s focus on energy efficiency and sustainability further boosts the adoption of CNC fiber lasers, as they reduce energy consumption and waste. This trend positions North America for significant market growth through 2032.

Get Customized Report as per Your Business Requirement - Enquiry Now

Some of the Major Players CNC Fiber Laser Market with their product:

IPG Photonics Corporation (High-power fiber lasers, pulsed fiber lasers)

TRUMPF GmbH + Co. KG (Industrial laser cutting systems, marking lasers)

Maxphotonics Co., Ltd. (Single-mode fiber lasers, multi-mode fiber lasers)

Coherent Inc. (Fiber laser modules, laser cutting solutions)

Newport Corporation (Precision laser optics, fiber laser systems)

Wuhan Raycus Fiber Laser Technologies Co., Ltd. (Continuous wave fiber lasers, MOPA fiber lasers)

Lumentum Operations LLC (High-precision fiber lasers, semiconductor lasers)

Fanuc Corporation (Laser systems for robotics, fiber laser cutting machines)

Furukawa Electric Co., Ltd. (High-power fiber lasers, specialty fiber lasers)

Keopsys S.A. (Custom fiber lasers, telecom lasers)

Fujikura Ltd. (Compact fiber lasers, high-performance splicing systems)

nLIGHT Inc. (Advanced industrial fiber lasers, compact high-power lasers)

Bystronic Laser AG (Laser cutting systems, fiber laser automation solutions)

Han’s Laser Technology Industry Group Co., Ltd. (Laser welding systems, fiber laser engravers)

Prima Industrie S.p.A. (Laser cutting and punching machines, fiber laser modules)

Trotec Laser GmbH (Small and medium-sized fiber laser engravers)

Amada Co., Ltd. (Fiber laser cutting systems, metal processing lasers)

Epilog Laser (Compact fiber lasers for engraving and marking)

Rofin-Sinar Technologies Inc. (Micro and macro material processing lasers)

Hypertherm Inc. (Industrial fiber laser cutters and plasma systems)

Mitsubishi Electric Corporation (Automated fiber laser systems, advanced optics)

Jenoptik AG (High-power laser sources, precision cutting systems)

List of suppliers for CNC fiber laser raw materials and components:

Corning Inc.

Thorlabs Inc.

II-VI Incorporated

Coherent Inc.

Lumentum Operations LLC

Furukawa Electric Co., Ltd.

IPG Photonics Corporation

Laserline GmbH

Polatis Ltd.

Fujikura Ltd.

SCHOTT AG

Sanken Electric Co., Ltd.

Mitsubishi Electric Corporation

Osram Opto Semiconductors

Acer Optoelectronics

Moxtek Inc.

Jenoptik AG

Nikon Corporation

Primes GmbH

Sumitomo Electric Industries, Ltd.

November 2024, TRUMPF unveiled the TruPrint 3000 at Formnext, featuring dual 700-watt lasers and integrated cooling for improved productivity and stronger parts. The upgrades enhance manufacturing for industries like automotive and aerospace, enabling faster, high-quality volume production.

December 2024, IPG Photonics Corp has launched the YLR-AMB series of dual-beam lasers for additive manufacturing, offering precision and efficiency with build rates exceeding 324cm³/hr. The lasers are optimized for materials like Ti-6Al-4V and feature a compact rack-mountable design, improving productivity and material efficiency.

October 2024, Coherent introduced a new CO₂ laser electro-optic modulator that enhances processing speeds and precision. This breakthrough enables higher power lasers, up to 1 kW, to accelerate cutting, drilling, and engraving processes in industries like microelectronics and medical device manufacturing.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 2.46 Billion |

| Market Size by 2032 | USD 4.60 Bllion |

| CAGR | CAGR of 7.20% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (CNC CO2 Laser Cutter, CNC Crystal Laser Cutter, CNC Fiber Laser Cutter) • By Type (Stationary Gantry Type, Movable Gantry Type) • By Application (Wood Working, Stone Working, Metal Working, Others) • By End User (Automotive, Building & Construction, Consumer Electronics, Aerospace & Defense, Medical, Energy & Power, Furniture, Transportation, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | IPG Photonics Corporation, TRUMPF GmbH + Co. KG, Maxphotonics Co., Ltd., Coherent Inc., Newport Corporation, Wuhan Raycus Fiber Laser Technologies Co., Ltd., Lumentum Operations LLC, Fanuc Corporation, Furukawa Electric Co., Ltd., Keopsys S.A., Fujikura Ltd., nLIGHT Inc., Bystronic Laser AG, Han’s Laser Technology Industry Group Co., Ltd., Prima Industrie S.p.A., Trotec Laser GmbH, Amada Co., Ltd., Epilog Laser, Rofin-Sinar Technologies Inc., Hypertherm Inc., Mitsubishi Electric Corporation, Jenoptik AG. |

| Key Drivers | • The increasing adoption of CNC fiber lasers in the automotive and aerospace industries is significantly boosting the growth of the CNC fiber laser market. |

| Restraints | • Competition from Alternative Cutting Methods - A Major Challenge for the CNC Fiber Laser Market. |

Ans: CNC Fiber Laser Market is anticipated to expand by 7.20% from 2024 to 2032.

Ans: IPG Photonics Corporation, TRUMPF GmbH + Co. KG, Maxphotonics Co., Ltd., Coherent Inc., Newport Corporation, Wuhan Raycus Fiber Laser Technologies Co., Ltd., Lumentum Operations LLC, Fanuc Corporation, Furukawa Electric Co., Ltd., Keopsys S.A., Fujikura Ltd.

Ans: Increased need for automation, Increasing demand for high-quality goods.

Ans: CNC Fiber Laser Market size was valued at USD 2.46 billion in 2023.

Ans: Asia-Pacific is dominating the CNC Fiber Laser Market.

Table of Content

1. Introduction

1.1 Market Definition

1.2 Scope (Inclusion and Exclusions)

1.3 Research Assumptions

2. Executive Summary

2.1 Market Overview

2.2 Regional Synopsis

2.3 Competitive Summary

3. Research Methodology

3.1 Top-Down Approach

3.2 Bottom-up Approach

3.3. Data Validation

3.4 Primary Interviews

4. Market Dynamics Impact Analysis

4.1 Market Driving Factors Analysis

4.1.1 Drivers

4.1.2 Restraints

4.1.3 Opportunities

4.1.4 Challenges

4.2 PESTLE Analysis

4.3 Porter’s Five Forces Model

5. Statistical Insights and Trends Reporting

5.1 Production and Sales Data

5.2 Technology and Performance Metrics

5.3 Automation and Industry 4.0 Adoption

5.4 Training and Workforce Development

6. Competitive Landscape

6.1 List of Major Companies, By Region

6.2 Market Share Analysis, By Region

6.3 Product Benchmarking

6.3.1 Product specifications and features

6.3.2 Pricing

6.4 Strategic Initiatives

6.4.1 Marketing and promotional activities

6.4.2 Distribution and supply chain strategies

6.4.3 Expansion plans and new product launches

6.4.4 Strategic partnerships and collaborations

6.5 Technological Advancements

6.6 Market Positioning and Branding

7. CNC Fiber Laser Market Segmentation, by Product

7.1 Chapter Overview

7.2 CNC CO2 Laser Cutter

7.2.1 CNC CO2 Laser Cutter Market Trends Analysis (2020-2032)

7.2.2 CNC CO2 Laser Cutter Market Size Estimates and Forecasts to 2032 (USD Billion)

7.3 CNC Crystal Laser Cutter

7.3.1 CNC Crystal Laser Cutter Market Trends Analysis (2020-2032)

7.3.2 CNC Crystal Laser Cutter Market Size Estimates and Forecasts to 2032 (USD Billion)

7.4 CNC Fiber Laser Cutter

7.4.1 CNC Fiber Laser Cutter Market Trends Analysis (2020-2032)

7.4.2 CNC Fiber Laser Cutter Market Size Estimates and Forecasts to 2032 (USD Billion)

8. CNC Fiber Laser Market Segmentation, by Type

8.1 Chapter Overview

8.2 Stationary Gantry Type

8.2.1 Stationary Gantry Type Market Trends Analysis (2020-2032)

8.2.2 Stationary Gantry Type Market Size Estimates and Forecasts to 2032 (USD Billion)

8.3 Movable Gantry Type

8.3.1 Movable Gantry Type Market Trends Analysis (2020-2032)

8.3.2 Movable Gantry Type Market Size Estimates and Forecasts to 2032 (USD Billion)

9. CNC Fiber Laser Market Segmentation, by Application

9.1 Chapter Overview

9.2 Wood Working

9.2.1 Wood Working Market Trends Analysis (2020-2032)

9.2.2 Wood Working Market Size Estimates and Forecasts to 2032 (USD Billion)

9.3 Stone Working

9.3.1 Stone Working Market Trends Analysis (2020-2032)

9.3.2 Stone Working Market Size Estimates and Forecasts to 2032 (USD Billion)

9.4 Metal Working

9.4.1 Metal Working Market Trends Analysis (2020-2032)

9.4.2 Metal Working Market Size Estimates and Forecasts to 2032 (USD Billion)

9.5 Others

9.5.1 Others Market Trends Analysis (2020-2032)

9.5.2 Others Market Size Estimates and Forecasts to 2032 (USD Billion)

10. CNC Fiber Laser Market Segmentation, by End User

10.1 Chapter Overview

10.2 Automotive

10.2.1 Automotive Market Trends Analysis (2020-2032)

10.2.2 Automotive Market Size Estimates and Forecasts to 2032 (USD Billion)

10.3 Building & Construction

10.3.1 Building & Construction Market Trends Analysis (2020-2032)

10.3.2 Building & Construction Market Size Estimates and Forecasts to 2032 (USD Billion)

10.4 Consumer Electronics

10.4.1 Consumer Electronics Market Trends Analysis (2020-2032)

10.4.2 Consumer Electronics Market Size Estimates and Forecasts to 2032 (USD Billion)

10.5 Aerospace & Defense

10.5.1 Aerospace & Defense Market Trends Analysis (2020-2032)

10.5.2 Aerospace & Defense Market Size Estimates and Forecasts to 2032 (USD Billion)

10.6 Medical

10.6.1 Medical Market Trends Analysis (2020-2032)

10.6.2 Medical Market Size Estimates and Forecasts to 2032 (USD Billion)

10.7 Energy & Power

10.7.1 Energy & Power Market Trends Analysis (2020-2032)

10.7.2 Energy & Power Market Size Estimates and Forecasts to 2032 (USD Billion)

10.8 Furniture

10.8.1 Furniture Market Trends Analysis (2020-2032)

10.8.2 Furniture Market Size Estimates and Forecasts to 2032 (USD Billion)

10.9 Transportation

10.10.1 Transportation Market Trends Analysis (2020-2032)

10.10.2 Transportation Market Size Estimates and Forecasts to 2032 (USD Billion)

10.10 Others

10.10.1 Others Market Trends Analysis (2020-2032)

10.10.2 Others Market Size Estimates and Forecasts to 2032 (USD Billion)

11. Regional Analysis

11.1 Chapter Overview

11.2 North America

11.2.1 Trends Analysis

11.2.2 North America CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.2.3 North America CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.2.4 North America CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.2.5 North America CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.2.6 North America CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.2.7 USA

11.2.7.1 USA CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.2.7.2 USA CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.2.7.3 USA CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.2.7.4 USA CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.2.8 Canada

11.2.8.1 Canada CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.2.8.2 Canada CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.2.8.3 Canada CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.2.8.4 Canada CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.2.9 Mexico

11.2.9.1 Mexico CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.2.9.2 Mexico CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.2.9.3 Mexico CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.2.9.4 Mexico CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3 Europe

11.3.1 Eastern Europe

11.3.1.1 Trends Analysis

11.3.1.2 Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.3.1.3 Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.4 Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.5 Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.6 Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.1.7 Poland

11.3.1.7.1 Poland CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.7.2 Poland CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.7.3 Poland CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.7.4 Poland CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.1.8 Romania

11.3.1.8.1 Romania CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.8.2 Romania CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.8.3 Romania CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.8.4 Romania CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.1.9 Hungary

11.3.1.9.1 Hungary CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.9.2 Hungary CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.9.3 Hungary CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.9.4 Hungary CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.1.10 Turkey

11.3.1.10.1 Turkey CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.10.2 Turkey CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.10.3 Turkey CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.10.4 Turkey CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.1.11 Rest of Eastern Europe

11.3.1.11.1 Rest of Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.1.11.2 Rest of Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.1.11.3 Rest of Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.1.11.4 Rest of Eastern Europe CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2 Western Europe

11.3.2.1 Trends Analysis

11.3.2.2 Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.3.2.3 Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.4 Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.5 Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.6 Western Europe CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.7 Germany

11.3.2.7.1 Germany CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.7.2 Germany CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.7.3 Germany CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.7.4 Germany CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.8 France

11.3.2.8.1 France CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.8.2 France CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.8.3 France CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.8.4 France CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.9 UK

11.3.2.9.1 UK CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.9.2 UK CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.9.3 UK CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.9.4 UK CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.10 Italy

11.3.2.10.1 Italy CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.10.2 Italy CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.10.3 Italy CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.10.4 Italy CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.11 Spain

11.3.2.11.1 Spain CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.11.2 Spain CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.11.3 Spain CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.11.4 Spain CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.12 Netherlands

11.3.2.12.1 Netherlands CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.12.2 Netherlands CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.12.3 Netherlands CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.12.4 Netherlands CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.13 Switzerland

11.3.2.13.1 Switzerland CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.13.2 Switzerland CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.13.3 Switzerland CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.13.4 Switzerland CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.14 Austria

11.3.2.14.1 Austria CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.14.2 Austria CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.14.3 Austria CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.14.4 Austria CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.3.2.15 Rest of Western Europe

11.3.2.15.1 Rest of Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.3.2.15.2 Rest of Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.3.2.15.3 Rest of Western Europe CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.3.2.15.4 Rest of Western Europe CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4 Asia-Pacific

11.4.1 Trends Analysis

11.4.2 Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.4.3 Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.4 Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.5 Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.6 Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.7 China

11.4.7.1 China CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.7.2 China CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.7.3 China CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.7.4 China CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.8 India

11.4.8.1 India CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.8.2 India CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.8.3 India CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.8.4 India CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.9 Japan

11.4.9.1 Japan CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.9.2 Japan CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.9.3 Japan CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.9.4 Japan CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.10 South Korea

11.4.10.1 South Korea CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.10.2 South Korea CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.10.3 South Korea CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.10.4 South Korea CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.11 Vietnam

11.4.11.1 Vietnam CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.11.2 Vietnam CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.11.3 Vietnam CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.11.4 Vietnam CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.12 Singapore

11.4.12.1 Singapore CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.12.2 Singapore CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.12.3 Singapore CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.12.4 Singapore CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.13 Australia

11.4.13.1 Australia CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.13.2 Australia CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.13.3 Australia CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.13.4 Australia CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.4.14 Rest of Asia-Pacific

11.4.14.1 Rest of Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.4.14.2 Rest of Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.4.14.3 Rest of Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.4.14.4 Rest of Asia-Pacific CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5 Middle East and Africa

11.5.1 Middle East

11.5.1.1 Trends Analysis

11.5.1.2 Middle East CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.5.1.3 Middle East CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.4 Middle East CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.5 Middle East CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.6 Middle East CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.1.7 UAE

11.5.1.7.1 UAE CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.7.2 UAE CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.7.3 UAE CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.7.4 UAE CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.1.8 Egypt

11.5.1.8.1 Egypt CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.8.2 Egypt CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.8.3 Egypt CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.8.4 Egypt CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.1.9 Saudi Arabia

11.5.1.9.1 Saudi Arabia CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.9.2 Saudi Arabia CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.9.3 Saudi Arabia CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.9.4 Saudi Arabia CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.1.10 Qatar

11.5.1.10.1 Qatar CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.10.2 Qatar CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.10.3 Qatar CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.10.4 Qatar CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.1.11 Rest of Middle East

11.5.1.11.1 Rest of Middle East CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.1.11.2 Rest of Middle East CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.1.11.3 Rest of Middle East CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.1.11.4 Rest of Middle East CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.2 Africa

11.5.2.1 Trends Analysis

11.5.2.2 Africa CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.5.2.3 Africa CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.2.4 Africa CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.2.5 Africa CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.2.6 Africa CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.2.7 South Africa

11.5.2.7.1 South Africa CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.2.7.2 South Africa CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.2.7.3 South Africa CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.2.7.4 South Africa CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.2.8 Nigeria

11.5.2.8.1 Nigeria CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.2.8.2 Nigeria CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.2.8.3 Nigeria CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.2.8.4 Nigeria CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.5.2.9 Rest of Africa

11.5.2.9.1 Rest of Africa CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.5.2.9.2 Rest of Africa CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.5.2.9.3 Rest of Africa CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.5.2.9.4 Rest of Africa CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.6 Latin America

11.6.1 Trends Analysis

11.6.2 Latin America CNC Fiber Laser Market Estimates and Forecasts, by Country (2020-2032) (USD Billion)

11.6.3 Latin America CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.6.4 Latin America CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.6.5 Latin America CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.6.6 Latin America CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.6.7 Brazil

11.6.7.1 Brazil CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.6.7.2 Brazil CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.6.7.3 Brazil CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.6.7.4 Brazil CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.6.8 Argentina

11.6.8.1 Argentina CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.6.8.2 Argentina CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.6.8.3 Argentina CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.6.8.4 Argentina CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.6.9 Colombia

11.6.9.1 Colombia CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.6.9.2 Colombia CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.6.9.3 Colombia CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.6.9.4 Colombia CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

11.6.10 Rest of Latin America

11.6.10.1 Rest of Latin America CNC Fiber Laser Market Estimates and Forecasts, by Product (2020-2032) (USD Billion)

11.6.10.2 Rest of Latin America CNC Fiber Laser Market Estimates and Forecasts, by Type (2020-2032) (USD Billion)

11.6.10.3 Rest of Latin America CNC Fiber Laser Market Estimates and Forecasts, by Application (2020-2032) (USD Billion)

11.6.10.4 Rest of Latin America CNC Fiber Laser Market Estimates and Forecasts, by End User (2020-2032) (USD Billion)

12. Company Profiles

12.1 IPG Photonics Corporation

12.1.1 Company Overview

12.1.2 Financial

12.1.3 Products/ Services Offered

12.1.4 SWOT Analysis

12.2 TRUMPF GmbH + Co. KG

12.2.1 Company Overview

12.2.2 Financial

12.2.3 Products/ Services Offered

12.2.4 SWOT Analysis

12.3 Maxphotonics Co., Ltd.

12.3.1 Company Overview

12.3.2 Financial

12.3.3 Products/ Services Offered

12.3.4 SWOT Analysis

12.4 Coherent Inc.

12.4.1 Company Overview

12.4.2 Financial

12.4.3 Products/ Services Offered

12.4.4 SWOT Analysis

12.5 Newport Corporation

12.5.1 Company Overview

12.5.2 Financial

12.5.3 Products/ Services Offered

12.5.4 SWOT Analysis

12.6 Wuhan Raycus Fiber Laser Technologies Co., Ltd.

12.6.1 Company Overview

12.6.2 Financial

12.6.3 Products/ Services Offered

12.6.4 SWOT Analysis

12.7 Lumentum Operations LLC

12.7.1 Company Overview

12.7.2 Financial

12.7.3 Products/ Services Offered

12.7.4 SWOT Analysis

12.8 Fanuc Corporation

12.8.1 Company Overview

12.8.2 Financial

12.8.3 Products/ Services Offered

12.8.4 SWOT Analysis

12.9 Furukawa Electric Co., Ltd.

12.9.1 Company Overview

12.9.2 Financial

12.9.3 Products/ Services Offered

12.9.4 SWOT Analysis

12.10 Keopsys S.A.

12.10.1 Company Overview

12.10.2 Financial

12.10.3 Products/ Services Offered

12.10.4 SWOT Analysis

13. Use Cases and Best Practices

14. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

By Product

CNC CO2 Laser Cutter

CNC Crystal Laser Cutter

CNC Fiber Laser Cutter

By Type

Stationary Gantry Type

Movable Gantry Type

By Application

Wood Working

Stone Working

Metal Working

Others

By End User

Automotive

Building & Construction

Consumer Electronics

Aerospace & Defense

Medical

Energy & Power

Furniture

Transportation

Others

Request for Segment Customization as per your Business Requirement: Segment Customization Request

REGIONAL COVERAGE:

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia-Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of the Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

Request for Country Level Research Report: Country Level Customization Request

Available Customization

With the given market data, SNS Insider offers customization as per the company’s specific needs. The following customization options are available for the report:

Product Analysis

Criss-Cross segment analysis (e.g. Product X Application)

Product Matrix which gives a detailed comparison of the product portfolio of each company

Geographic Analysis

Additional countries in any of the regions

Company Information

Detailed analysis and profiling of additional market players (Up to five)

The Refrigeration Monitoring Market Size was valued at USD 8.38 Billion in 2023 and is expected to grow at 7.84% CAGR to reach USD 16.46 Billion by 2032.

The Low Voltage Switchgear Market Size was valued at USD 41.83 billion in 2023 and is expected to grow at 8.15% CAGR to reach USD 84.29 billion by 2032.

The Power Electronics Market Size was valued at USD 36.28 Billion in 2023 and is expected to grow at a CAGR of 5.78% to reach USD 60.10 Billion by 2032.

The Home Audio Equipment Market was USD 1.50 Billion in 2023 and is expected to reach USD 2.35 Billion by 2032, growing at a CAGR of 5.15% by 2024-2032.

The Non-Destructive Inspection Equipment Market was valued at USD 3.2 Billion in 2023 and is expected to reach USD 5.7 Billion by 2032, growing at a CAGR of 6.04% from 2024-2032.

The Smart Container Market size was valued at USD 4.17 Billion in 2023 and expected to grow at a CAGR of 18.06% to reach USD 18.58 Billion by 2032.

Hi! Click one of our member below to chat on Phone