To get more information on Additive Manufacturing Market - Request Free Sample Report

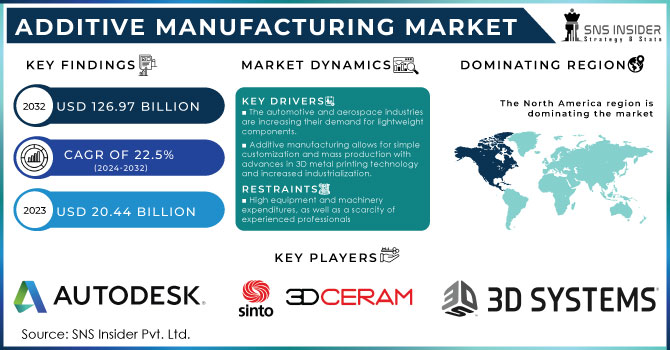

The Additive Manufacturing Market Size was valued at USD 20.44 billion in 2023 and is expected to reach USD 126.97 billion by 2032 and grow at a CAGR of 22.5% over the forecast period 2024-2032.

The additive manufacturing market growing due to several factors such as, the rise in demand of efficient prototyping, especially in healthcare, automotive, and aerospace & defense. These industries are highly depends on the rapid and cost-effective creation of prototypes for designs and conduct testing. Additive manufacturing fulfill this need by the creation of complex prototypes in a short time spam and the cost is low as compared to traditional methods. The example is the development of multi-material printing, which have the ability to create objects with a combination of functionalities in a single print. This innovative product design and lighter, stronger, and more efficient components in various sectors. For Instance, November 2023, Autodesk Inc. unveiled a new AI technology integrated in its products. This innovation, called Autodesk AI, is designed to provide users with intelligent assistance and the ability to generate creative solutions. By automating repetitive tasks and gives important suggestions, Autodesk aims to streamline workflows, reduces errors, and lead to evolve needs of its design and engineering customers.

Traditional manufacturing, additive manufacturing provides flexibility. No need of expensive tool changes for small adjustment. Additive manufacturing adjust designs and parameters on the specific customer needs. This give ability to businesses to create personalized products and adopt on-demand production, minimizing stock issues and overproduction.

The increased need for prototype applications from numerous industries and industrial verticals, including healthcare, automotive, aerospace, and military, as well as intensive research and development in 3D printing, are projected to fuel market expansion.

Market Dynamics

Drivers

The automotive and aerospace industries are increasing their demand for lightweight components.

Additive manufacturing allows for simple customization and mass production with advances in 3D metal printing technology and increased industrialization.

Development in 3D metal printing technology are rising the growth of the market. Imagine high-performance components produced for aerospace, automotive, and medical industries components which are impossible to create by using traditional methods. This with the increasing industrialization of Additive Manufacturing, increases the ability to achieve mass production and efficiency with providing easy customization for the produced parts. This rises the design freedom, of lighter and stronger parts, and also faster the time to market of new products. Additive Manufacturing is changing manufacturing practices by giving the power of scale with the benefits of creation. For Instance, the Additive Manufacturing have impact on General Electric's (GE) LEAP engine. These jet engines use 3D-printed fuel nozzles, a component is important for the fuel combustion. Also, these nozzles are assembled from approximately 20 separate pieces. Through AM, GE was able to consolidate the design into a single, lighter-weight nozzle. This innovation reduced part count and assembly time and improved fuel efficiency by 15% as compared to previous models.

Restraint

High equipment and machinery expenditures, as well as a scarcity of experienced professionals.

Additive Manufacturing machines are expensive, ranging from a few thousand dollars for basic models to hundreds of thousands for industrial grade systems. This cost can be lower for smaller companies or those just starting Additive Manufacturing. Also, the cost of materials used in Additive Manufacturing is higher as compared to traditional manufacturing methods for certain applications. Operating and maintaining Additive Manufacturing equipment requires specialized knowledge and skilled workers. There is a current shortage of professionals with the necessary skills to design for Additive Manufacturing.

Key Market Segmentation

By Component

Hardware

Software

Services

By Printer Type

Desktop 3D Printer

Industrial 3D Printer

The Industrial 3D Printer dominated the segment of additive manufacturing market with more than 75.4% of market share in 2023. This dominance is due to rises the use of Industrial 3D Printer in various industries like automotive, electronics, and healthcare. From prototyping and design to creating tools, industrial 3D printers are helping in many industries, with the global adoption. These printers are user friendly and cost effective.

By Technology

Stereolithography

Fuse Deposition Modeling

Selective Laser Sintering

Direct Metal Laser Sintering

Polyjet Printing

Inkjet Printing

Electron Beam Melting

Laser Metal Deposition

Digital Light Processing

Laminated Object Manufacturing

Others

The Stereolithography segment dominated the additive manufacturing market with more than 10% of market share in 2023. This segment is dominated due to, it has user-friendly nature and ability to produce high quantity of parts. High research and development activities from leading experts are constantly helps in the growth of the additive manufacturing market. These advancements are rising the new, efficient, and reliable printing technologies with unique advantages. This constant evolution definitely gives more advanced 3D printing options.

By Software

Design Software

Inspection Software

Printer Software

Scanning Software

The Design Software segment dominated the additive manufacturing market with more than 35.4% of market share in 2023. Design Software segment dominated due to several factors such as, freedom in design complex geometries, incorporate internal lattices, and personalize designs. The integration with 3D printers allows direct file transfer and print, which is time saving and minimizing errors. Software can analyze design and provide suggestion about material usage and internal structures, which leads to cost savings. Teams can work on the same 3D model simultaneously, enhancing better communication and streamlining the design process.

The design software continues to evolve, it will remain a driving force of the additive manufacturing market

By Application

Prototyping

Tooling

Functional Parts

By Vertical

Industrial Additive Manufacturing

Desktop Additive Manufacturing

REGIONAL COVERAGE

North America

US

Canada

Mexico

Europe

Eastern Europe

Poland

Romania

Hungary

Turkey

Rest of Eastern Europe

Western Europe

Germany

France

UK

Italy

Spain

Netherlands

Switzerland

Austria

Rest of Western Europe

Asia Pacific

China

India

Japan

South Korea

Vietnam

Singapore

Australia

Rest of Asia Pacific

Middle East & Africa

Middle East

UAE

Egypt

Saudi Arabia

Qatar

Rest of Middle East

Africa

Nigeria

South Africa

Rest of Africa

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

REGIONAL ANALYSES

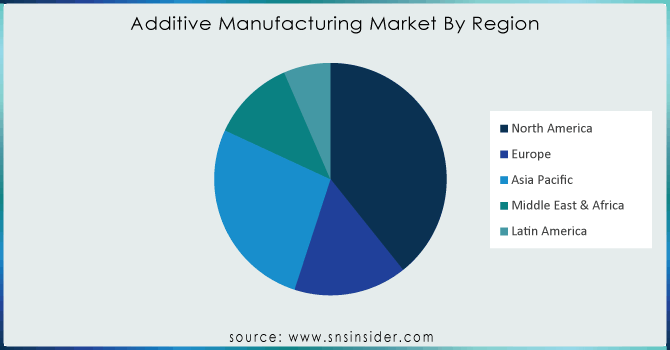

North America dominated the Additive Manufacturing Market with more than 33.8% of the market share in 2023. This dominance is due to the presence of developed countries like the US and Canada which are known for their early adoption in technologies. North America have developed healthcare infrastructure and they are very prone to adopt new technologies.

Europe is the second dominating region of the additive manufacturing market due to, their technological knowledge, and presence of established market players who constantly innovating.

The Asia Pacific region is the fastest growing region for the additive manufacturing market. This growth is due to this region is rapidly becoming a manufacturing center for industries like automotive, healthcare, and consumer electronics. Additive Manufacturing give an opportunity to streamline and innovate production processes. Rapidly growing cities in the Asia Pacific region are rising the demand for customized and efficient solutions. 3D printing gives scope for construction and infrastructure development.

Need any customization research on Additive Manufacturing Market - Enquiry Now

The Major Players are 3D Systems, Inc., 3DCeram, Arcam AB, Autodesk, Inc., Canon, Inc., Dassault Systemes, EnvisionTec, Inc., EOS (Electro Optical Systems) GmbH, ExOne, GE Additive, HP Inc., madeinspace.us, Materialise NV, Optomec, Inc., Organovo Holdings Inc., Proto Labs, Inc., Shapeways, Inc., Stratasys, Ltd, Tiertime, Voxeljet AG and Other Players

Recent Developments:

In March 2023, 3D Systems Inc, unveiled the NextDent LCD1, a user-friendly, small-sized 3D printing platform. With printer, they introduced two innovative materials: NextDent Cast and NextDent Base.

In November 2023, Autodesk Inc, unveiled its new AI technology. This innovative addition integrates with existing Autodesk products, offering a powerful boost to design and manufacturing workflows.

In February 2022, Dassault Systèmes and Cadence Design Systems announced a strategic partnership. To provide cutting-edge solutions for building complex electronic systems. This collaboration targets a large range of industries, from high-tech and healthcare to transportation and aerospace.

| Report Attributes | Details |

| Market Size in 2023 | US$ 20.44 Bn |

| Market Size by 2032 | US$ 126.97 Bn |

| CAGR | CAGR of 22.5% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Component (Hardware, Software, Services) • By Printer Type (Desktop 3D Printer, Industrial 3D Printer) • By Technology (Stereolithography, Fuse Deposition Modeling, Selective Laser Sintering, Direct Metal Laser Sintering, Polyjet Printing, Inkjet Printing, Electron Beam Melting, Laser Metal Deposition, Digital Light Processing, Laminated Object Manufacturing, Others) • By Software (Design Software, Inspection Software, Printer Software, Scanning Software) • By Application (Prototyping, Tooling, Functional Parts) • By Vertical Outlook (Industrial Additive Manufacturing (Automotive, Aerospace & Defense, Healthcare, Consumer Electronics, Power & Energy, Others), Desktop Additive Manufacturing (Educational Purpose, Fashion & Jewelry, Objects, Dental, Food, Others)) • By Material (Polymer, Metal, Ceramic) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]). Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia Rest of Latin America) |

| Company Profiles | Stratasys, Ltd, Materialise NV, EnvisionTec, Inc, 3D Systems, Inc, GE Additive, Autodesk Inc, Made In Space, Canon Inc, Voxeljet AG |

| Key Drivers | • The automotive and aerospace industries are increasing their demand for lightweight components. • Advantages of additive manufacturing in a variety of end-user sectors. • Additive manufacturing allows for simple customization and mass production. • Advances in 3D metal printing technology and increased industrialization. |

| Market Restraints | • High equipment and machinery expenditures, as well as a scarcity of experienced professionals |

Ans: The Additive Manufacturing Market is expected to grow at 20.6% CAGR from 2023 to 2030.

Ans: The Additive Manufacturing Market is anticipated to reach USD 61.93 billion By 2030.

Ans: The leading participants in the,tratasys, Ltd, Materialise NV, EnvisionTec, Inc, 3D Systems, Inc, GE Additive.

Ans: In 2021, the stereolithography category topped the global additive manufacturing market, accounting for more than 8.8% of global revenue.

Ans: Yes, you may request customization based on your company's needs.

TABLE OF CONTENTS

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Industry Flowchart

3. Research Methodology

4. Market Dynamics

4.1 Drivers

4.2 Restraints

4.3 Opportunities

4.4 Challenge

5. Porter’s 5 Forces Model

6. Pest Analysis

7. Additive Manufacturing Market Segmentation, By Component

7.1 Introduction

7.2 Hardware

7.3 Software

7.4 Services

8. Additive Manufacturing Market Segmentation, By Printer Type

8.1 Introduction

8.2 Desktop 3D Printer

8.3 Industrial 3D Printer

9. Additive Manufacturing Market Segmentation, By Technology

9.1 Introduction

9.2 Stereolithography

9.3 Fuse Deposition Modeling

9.4 Selective Laser Sintering

9.5 Direct Metal Laser Sintering

9.6 Polyjet Printing

9.7 Inkjet Printing

9.8 Electron Beam Melting

9.9 Laser Metal Deposition

9.10 Digital Light Processing

9.11 Laminated Object Manufacturing

9.12 Others

10. Additive Manufacturing Market Segmentation, By Software

10.1 Introduction

10.2 Design Software

10.3 Inspection Software

10.4 Printer Software

10.5 Scanning Software

11. Additive Manufacturing Market Segmentation, By Application

11.1 Introduction

11.2 Prototyping

11.3 Tooling

11.4 Functional Parts

12. Additive Manufacturing Market Segmentation, By Vertical

12.1 Introduction

12.2 Industrial Additive Manufacturing

12.3 Desktop Additive Manufacturing

13. Regional Analysis

13.1 Introduction

13.2 North America

13.2.1 Trend Analysis

13.2.2 North America Additive Manufacturing Market By Country

13.2.3 North America Additive Manufacturing Market By Component

13.2.4 North America Additive Manufacturing Market By Printer Type

13.2.5 North America Additive Manufacturing Market By Technology

13.2.6 North America Additive Manufacturing Market , By Software

13.2.7 North America Additive Manufacturing Market , By Application

13.2.8 North America Additive Manufacturing Market , By Vertical

13.2.9 USA

13.2.9.1 USA Additive Manufacturing Market By Component

13.2.9.2 USA Additive Manufacturing Market By Printer Type

13.2.9.3 USA Additive Manufacturing Market By Technology

13.2.9.4 USA Additive Manufacturing Market , By Software

13.2.9.5 USA Additive Manufacturing Market , By Application

13.2.9.6 USA Additive Manufacturing Market , By Vertical

13.2.10 Canada

13.2.10.1 Canada Additive Manufacturing Market By Component

13.2.10.2 Canada Additive Manufacturing Market By Printer Type

13.2.10.3 Canada Additive Manufacturing Market By Technology

13.2.10.4 Canada Additive Manufacturing Market , By Software

13.2.10.5 Canada Additive Manufacturing Market , By Application

13.2.10.6 Canada Additive Manufacturing Market , By Vertical

13.2.11 Mexico

13.2.11.1 Mexico Additive Manufacturing Market By Component

13.2.11.2 Mexico Additive Manufacturing Market By Printer Type

13.2.11.3 Mexico Additive Manufacturing Market By Technology

13.2.11.4 Mexico Additive Manufacturing Market , By Software

13.2.11.5 Mexico Additive Manufacturing Market , By Application

13.2.11.6 Mexico Additive Manufacturing Market , By Vertical

13.3 Europe

13.3.1 Trend Analysis

13.3.2 Eastern Europe

13.3.2.1 Eastern Europe Additive Manufacturing Market By Country

13.3.2.2 Eastern Europe Additive Manufacturing Market By Component

13.3.2.3 Eastern Europe Additive Manufacturing Market By Printer Type

13.3.2.4 Eastern Europe Additive Manufacturing Market By Technology

13.3.2.5 Eastern Europe Additive Manufacturing Market By Software

13.3.2.6 Eastern Europe Additive Manufacturing Market , By Application

13.3.2.7 Eastern Europe Additive Manufacturing Market , By Vertical

13.3.2.8 Poland

13.3.2.8.1 Poland Additive Manufacturing Market By Component

13.3.2.8.2 Poland Additive Manufacturing Market By Printer Type

13.3.2.8.3 Poland Additive Manufacturing Market By Technology

13.3.2.8.4 Poland Additive Manufacturing Market By Software

13.3.2.8.5 Poland Additive Manufacturing Market , By Application

13.3.2.8.6 Poland Additive Manufacturing Market , By Vertical

13.3.2.9 Romania

13.3.2.9.1 Romania Additive Manufacturing Market By Component

13.3.2.9.2 Romania Additive Manufacturing Market By Printer Type

13.3.2.9.3 Romania Additive Manufacturing Market By Technology

13.3.2.9.4 Romania Additive Manufacturing Market By Software

13.3.2.9.5 Romania Additive Manufacturing Market , By Application

13.3.2.9.6 Romania Additive Manufacturing Market , By Vertical

13.3.2.10 Hungary

13.3.2.10.1 Hungary Additive Manufacturing Market By Component

13.3.2.10.2 Hungary Additive Manufacturing Market By Printer Type

13.3.2.10.3 Hungary Additive Manufacturing Market By Technology

13.3.2.10.4 Hungary Additive Manufacturing Market By Software

13.3.2.10.5 Hungary Additive Manufacturing Market , By Application

13.3.2.10.6 Hungary Additive Manufacturing Market , By Vertical

13.3.2.11 Turkey

13.3.2.11.1 Turkey Additive Manufacturing Market By Component

13.3.2.11.2 Turkey Additive Manufacturing Market By Printer Type

13.3.2.11.3 Turkey Additive Manufacturing Market By Technology

13.3.2.11.4 Turkey Additive Manufacturing Market By Software

13.3.2.11.5 Turkey Additive Manufacturing Market , By Application

13.3.2.11.6 Turkey Additive Manufacturing Market , By Vertical

13.3.2.12 Rest of Eastern Europe

13.3.2.12.1 Rest of Eastern Europe Additive Manufacturing Market By Component

13.3.2.12.2 Rest of Eastern Europe Additive Manufacturing Market By Printer Type

13.3.2.12.3 Rest of Eastern Europe Additive Manufacturing Market By Technology

13.3.2.12.4 Rest of Eastern Europe Additive Manufacturing Market By Software

13.3.2.12.5 Rest of Eastern Europe Additive Manufacturing Market , By Application

13.3.2.12.6 Rest of Eastern Europe Additive Manufacturing Market , By Vertical

13.3.3 Western Europe

13.3.3.1 Western Europe Additive Manufacturing Market By Country

13.3.3.2 Western Europe Additive Manufacturing Market By Component

13.3.3.3 Western Europe Additive Manufacturing Market By Printer Type

13.3.3.4 Western Europe Additive Manufacturing Market By Technology

13.3.3.5 Western Europe Additive Manufacturing Market By Software

13.3.3.6 Western Europe Additive Manufacturing Market , By Application

13.3.3.7 Western Europe Additive Manufacturing Market , By Vertical

13.3.3.8 Germany

13.3.3.8.1 Germany Additive Manufacturing Market By Component

13.3.3.8.2 Germany Additive Manufacturing Market By Printer Type

13.3.3.8.3 Germany Additive Manufacturing Market By Technology

13.3.3.8.4 Germany Additive Manufacturing Market By Software

13.3.3.8.5 Germany Additive Manufacturing Market , By Application

13.3.3.8.6 Germany Additive Manufacturing Market , By Vertical

13.3.3.9 France

13.3.3.9.1 France Additive Manufacturing Market By Component

13.3.3.9.2 France Additive Manufacturing Market By Printer Type

13.3.3.9.3 France Additive Manufacturing Market By Technology

13.3.3.9.4 France Additive Manufacturing Market By Software

13.3.3.9.5 France Additive Manufacturing Market , By Application

13.3.3.9.6 France Additive Manufacturing Market , By Vertical

13.3.3.10 UK

13.3.3.10.1 UK Additive Manufacturing Market By Component

13.3.3.10.2 UK Additive Manufacturing Market By Printer Type

13.3.3.10.3 UK Additive Manufacturing Market By Technology

13.3.3.10.4 UK Additive Manufacturing Market By Software

13.3.3.10.5 UK Additive Manufacturing Market , By Application

13.3.3.10.6 UK Additive Manufacturing Market , By Vertical

13.3.3.11 Italy

13.3.3.11.1 Italy Additive Manufacturing Market By Component

13.3.3.11.2 Italy Additive Manufacturing Market By Printer Type

13.3.3.11.3 Italy Additive Manufacturing Market By Technology

13.3.3.11.4 Italy Additive Manufacturing Market By Software

13.3.3.11.5 Italy Additive Manufacturing Market , By Application

13.3.3.11.6 Italy Additive Manufacturing Market , By Vertical

13.3.3.12 Spain

13.3.3.12.1 Spain Additive Manufacturing Market By Component

13.3.3.12.2 Spain Additive Manufacturing Market By Printer Type

13.3.3.12.3 Spain Additive Manufacturing Market By Technology

13.3.3.12.4 Spain Additive Manufacturing Market By Software

13.3.3.12.5 Spain Additive Manufacturing Market , By Application

13.3.3.12.6 Spain Additive Manufacturing Market , By Vertical

13.3.3.13 Netherlands

13.3.3.13.1 Netherlands Additive Manufacturing Market By Component

13.3.3.13.2 Netherlands Additive Manufacturing Market By Printer Type

13.3.3.13.3 Netherlands Additive Manufacturing Market By Technology

13.3.3.13.4 Netherlands Additive Manufacturing Market By Software

13.3.3.13.5 Netherlands Additive Manufacturing Market , By Application

13.3.3.13.6 Netherlands Additive Manufacturing Market , By Vertical

13.3.3.14 Switzerland

13.3.3.14.1 Switzerland Additive Manufacturing Market By Component

13.3.3.14.2 Switzerland Additive Manufacturing Market By Printer Type

13.3.3.14.3 Switzerland Additive Manufacturing Market By Technology

13.3.3.14.4 Switzerland Additive Manufacturing Market By Software

13.3.3.14.5 Switzerland Additive Manufacturing Market , By Application

13.3.3.14.6 Switzerland Additive Manufacturing Market , By Vertical

13.3.3.15 Austria

13.3.3.15.1 Austria Additive Manufacturing Market By Component

13.3.3.15.2 Austria Additive Manufacturing Market By Printer Type

13.3.3.15.3 Austria Additive Manufacturing Market By Technology

13.3.3.15.4 Austria Additive Manufacturing Market By Software

13.3.3.15.5 Austria Additive Manufacturing Market , By Application

13.3.3.15.6 Austria Additive Manufacturing Market , By Vertical

13.3.3.16 Rest of Western Europe

13.3.3.16.1 Rest of Western Europe Additive Manufacturing Market By Component

13.3.3.16.2 Rest of Western Europe Additive Manufacturing Market By Printer Type

13.3.3.16.3 Rest of Western Europe Additive Manufacturing Market By Technology

13.3.3.16.4 Rest of Western Europe Additive Manufacturing Market By Software

13.3.3.16.5 Rest of Western Europe Additive Manufacturing Market , By Application

13.3.3.16.6 Rest of Western Europe Additive Manufacturing Market , By Vertical

13.4 Asia-Pacific

13.4.1 Trend Analysis

13.4.2 Asia-Pacific Additive Manufacturing Market By country

13.4.3 Asia-Pacific Additive Manufacturing Market By Component

13.4.4 Asia-Pacific Additive Manufacturing Market By Printer Type

13.4.5 Asia-Pacific Additive Manufacturing Market By Technology

13.4.6 Asia-Pacific Additive Manufacturing Market By Software

13.4.7 Asia-Pacific Additive Manufacturing Market , By Application

13.4.8 Asia-Pacific Additive Manufacturing Market , By Vertical

13.4.9 China

13.4.9.1 China Additive Manufacturing Market By Component

13.4.9.2 China Additive Manufacturing Market By Printer Type

13.4.9.3 China Additive Manufacturing Market By Technology

13.4.9.4 China Additive Manufacturing Market By Software

13.4.9.5 China Additive Manufacturing Market , By Application

13.4.9.6 China Additive Manufacturing Market , By Vertical

13.4.10 India

13.4.10.1 India Additive Manufacturing Market By Component

13.4.10.2 India Additive Manufacturing Market By Printer Type

13.4.10.3 India Additive Manufacturing Market By Technology

13.4.10.4 India Additive Manufacturing Market By Software

13.4.10.5 India Additive Manufacturing Market , By Application

13.4.10.6 India Additive Manufacturing Market , By Vertical

13.4.11 Japan

13.4.11.1 Japan Additive Manufacturing Market By Component

13.4.11.2 Japan Additive Manufacturing Market By Printer Type

13.4.11.3 Japan Additive Manufacturing Market By Technology

13.4.11.4 Japan Additive Manufacturing Market By Software

13.4.11.5 Japan Additive Manufacturing Market , By Application

13.4.11.6 Japan Additive Manufacturing Market , By Vertical

13.4.12 South Korea

13.4.12.1 South Korea Additive Manufacturing Market By Component

13.4.12.2 South Korea Additive Manufacturing Market By Printer Type

13.4.12.3 South Korea Additive Manufacturing Market By Technology

13.4.12.4 South Korea Additive Manufacturing Market By Software

13.4.12.5 South Korea Additive Manufacturing Market , By Application

13.4.12.6 South Korea Additive Manufacturing Market , By Vertical

13.4.13 Vietnam

13.4.13.1 Vietnam Additive Manufacturing Market By Component

13.4.13.2 Vietnam Additive Manufacturing Market By Printer Type

13.4.13.3 Vietnam Additive Manufacturing Market By Technology

13.4.13.4 Vietnam Additive Manufacturing Market By Software

13.4.13.5 Vietnam Additive Manufacturing Market , By Application

13.4.13.6 Vietnam Additive Manufacturing Market , By Vertical

13.4.14 Singapore

13.4.14.1 Singapore Additive Manufacturing Market By Component

13.4.14.2 Singapore Additive Manufacturing Market By Printer Type

13.4.14.3 Singapore Additive Manufacturing Market By Technology

13.4.14.4 Singapore Additive Manufacturing Market By Software

13.4.14.5 Singapore Additive Manufacturing Market , By Application

13.4.14.6 Singapore Additive Manufacturing Market , By Vertical

13.4.15 Australia

13.4.15.1 Australia Additive Manufacturing Market By Component

13.4.15.2 Australia Additive Manufacturing Market By Printer Type

13.4.15.3 Australia Additive Manufacturing Market By Technology

13.4.15.4 Australia Additive Manufacturing Market By Software

13.4.15.5 Australia Additive Manufacturing Market , By Application

13.4.15.6 Australia Additive Manufacturing Market , By Vertical

13.4.16 Rest of Asia-Pacific

13.4.16.1 Rest of Asia-Pacific Additive Manufacturing Market By Component

13.4.16.2 Rest of Asia-Pacific Additive Manufacturing Market By Printer Type

13.4.16.3 Rest of Asia-Pacific Additive Manufacturing Market By Technology

13.4.16.4 Rest of Asia-Pacific Additive Manufacturing Market By Software

13.4.16.5 Rest of Asia-Pacific Additive Manufacturing Market , By Application

13.4.16.6 Rest of Asia-Pacific Additive Manufacturing Market , By Vertical

13.5 Middle East & Africa

13.5.1 Trend Analysis

13.5.2 Middle East

13.5.2.1 Middle East Additive Manufacturing Market By Country

13.5.2.2 Middle East Additive Manufacturing Market By Component

13.5.2.3 Middle East Additive Manufacturing Market By Printer Type

13.5.2.4 Middle East Additive Manufacturing Market By Technology

13.5.2.5 Middle East Additive Manufacturing Market By Software

13.5.2.6 Middle East Additive Manufacturing Market , By Application

13.5.2.7 Middle East Additive Manufacturing Market , By Vertical

13.5.2.8 UAE

13.5.2.8.1 UAE Additive Manufacturing Market By Component

13.5.2.8.2 UAE Additive Manufacturing Market By Printer Type

13.5.2.8.3 UAE Additive Manufacturing Market By Technology

13.5.2.8.4 UAE Additive Manufacturing Market By Software

13.5.2.8.5 UAE Additive Manufacturing Market , By Application

13.5.2.8.6 UAE Additive Manufacturing Market , By Vertical

13.5.2.9 Egypt

13.5.2.9.1 Egypt Additive Manufacturing Market By Component

13.5.2.9.2 Egypt Additive Manufacturing Market By Printer Type

13.5.2.9.3 Egypt Additive Manufacturing Market By Technology

13.5.2.9.4 Egypt Additive Manufacturing Market By Software

13.5.2.9.5 Egypt Additive Manufacturing Market , By Application

13.5.2.9.6 Egypt Additive Manufacturing Market , By Vertical

13.5.2.10 Saudi Arabia

13.5.2.10.1 Saudi Arabia Additive Manufacturing Market By Component

13.5.2.10.2 Saudi Arabia Additive Manufacturing Market By Printer Type

13.5.2.10.3 Saudi Arabia Additive Manufacturing Market By Technology

13.5.2.10.4 Saudi Arabia Additive Manufacturing Market By Software

13.5.2.10.5 Saudi Arabia Additive Manufacturing Market , By Application

13.5.2.10.6 Saudi Arabia Additive Manufacturing Market , By Vertical

13.5.2.11 Qatar

13.5.2.11.1 Qatar Additive Manufacturing Market By Component

13.5.2.11.2 Qatar Additive Manufacturing Market By Printer Type

13.5.2.11.3 Qatar Additive Manufacturing Market By Technology

13.5.2.11.4 Qatar Additive Manufacturing Market By Software

13.5.2.11.5 Qatar Additive Manufacturing Market , By Application

13.5.2.11.6 Qatar Additive Manufacturing Market , By Vertical

13.5.2.12 Rest of Middle East

13.5.2.12.1 Rest of Middle East Additive Manufacturing Market By Component

13.5.2.12.2 Rest of Middle East Additive Manufacturing Market By Printer Type

13.5.2.12.3 Rest of Middle East Additive Manufacturing Market By Technology

13.5.2.12.4 Rest of Middle East Additive Manufacturing Market By Software

13.5.2.12.5 Rest of Middle East Additive Manufacturing Market , By Application

13.5.2.12.6 Rest of Middle East Additive Manufacturing Market , By Vertical

13.5.3 Africa

13.5.3.1 Africa Additive Manufacturing Market By Country

13.5.3.2 Africa Additive Manufacturing Market By Component

13.5.3.3 Africa Additive Manufacturing Market By Printer Type

13.5.3.4 Africa Additive Manufacturing Market By Technology

13.5.3.5 Africa Additive Manufacturing Market By Software

13.5.3.6 Africa Additive Manufacturing Market , By Application

13.5.3.7 Africa Additive Manufacturing Market , By Vertical

13.5.3.8 Nigeria

13.5.3.8.1 Nigeria Additive Manufacturing Market By Component

13.5.3.8.2 Nigeria Additive Manufacturing Market By Printer Type

13.5.3.8.3 Nigeria Additive Manufacturing Market By Technology

13.5.3.8.4 Nigeria Additive Manufacturing Market By Software

13.5.3.8.5 Nigeria Additive Manufacturing Market , By Application

13.5.3.8.6 Nigeria Additive Manufacturing Market , By Vertical

13.5.3.9 South Africa

13.5.3.9.1 South Africa Additive Manufacturing Market By Component

13.5.3.9.2 South Africa Additive Manufacturing Market By Printer Type

13.5.3.9.3 South Africa Additive Manufacturing Market By Technology

13.5.3.9.4 South Africa Additive Manufacturing Market By Software

13.5.3.9.5 South Africa Additive Manufacturing Market , By Application

13.5.3.9.6 South Africa Additive Manufacturing Market , By Vertical

13.5.3.10 Rest of Africa

13.5.3.10.1 Rest of Africa Additive Manufacturing Market By Component

13.5.3.10.2 Rest of Africa Additive Manufacturing Market By Printer Type

13.5.3.10.3 Rest of Africa Additive Manufacturing Market By Technology

13.5.3.10.4 Rest of Africa Additive Manufacturing Market By Software

13.5.3.10.5 Rest of Africa Additive Manufacturing Market , By Application

13.5.3.10.6 Rest of Africa Additive Manufacturing Market , By Vertical

13.6 Latin America

13.6.1 Trend Analysis

13.6.2 Latin America Additive Manufacturing Market By country

13.6.3 Latin America Additive Manufacturing Market By Component

13.6.4 Latin America Additive Manufacturing Market By Printer Type

13.6.5 Latin America Additive Manufacturing Market By Technology

13.6.6 Latin America Additive Manufacturing Market By Software

13.6.7 Latin America Additive Manufacturing Market , By Application

13.6.8 Latin America Additive Manufacturing Market , By Vertical

13.6.9 Brazil

13.6.9.1 Brazil Additive Manufacturing Market By Component

13.6.9.2 Brazil Additive Manufacturing Market By Printer Type

13.6.9.3 Brazil Additive Manufacturing Market By Technology

13.6.9.4 Brazil Additive Manufacturing Market By Software

13.6.9.5 Brazil Additive Manufacturing Market , By Application

13.6.9.6 Brazil Additive Manufacturing Market , By Vertical

13.6.10 Argentina

13.6.10.1 Argentina Additive Manufacturing Market By Component

13.6.10.2 Argentina Additive Manufacturing Market By Printer Type

13.6.10.3 Argentina Additive Manufacturing Market By Technology

13.6.10.4 Argentina Additive Manufacturing Market By Software

13.6.10.5 Argentina Additive Manufacturing Market , By Application

13.6.10.6 Argentina Additive Manufacturing Market , By Vertical

13.6.11 Colombia

13.6.11.1 Colombia Additive Manufacturing Market By Component

13.6.11.2 Colombia Additive Manufacturing Market By Printer Type

13.6.11.3 Colombia Additive Manufacturing Market By Technology

13.6.11.4 Colombia Additive Manufacturing Market By Software

13.6.11.5 Colombia Additive Manufacturing Market , By Application

13.6.11.6 Colombia Additive Manufacturing Market , By Vertical

13.6.12 Rest of Latin America

13.6.12.1 Rest of Latin America Additive Manufacturing Market By Component

13.6.12.2 Rest of Latin America Additive Manufacturing Market By Printer Type

13.6.12.3 Rest of Latin America Additive Manufacturing Market By Technology

13.6.12.4 Rest of Latin America Additive Manufacturing Market By Software

13.6.12.5 Rest of Latin America Additive Manufacturing Market , By Application

13.6.12.6 Rest of Latin America Additive Manufacturing Market , By Vertical

14 Company Profiles

14.1 3D Systems, Inc.

14.1.1 Company Overview

14.1.2 Financial

14.1.3 Products/ Services Offered

14.1.4 The SNS View

14.2 3DCeram

14.2.1 Company Overview

14.2.2 Financial

14.2.3 Products/ Services Offered

14.2.4 The SNS View

14.3 Arcam AB

14.3.1 Company Overview

14.3.2 Financial

14.3.3 Products/ Services Offered

14.3.4 The SNS View

14.4 Autodesk, Inc.

14.4.1 Company Overview

14.4.2 Financial

14.4.3 Products/ Services Offered

14.4.4 The SNS View

14.5 Canon, Inc.

14.5.1 Company Overview

14.5.2 Financial

14.5.3 Products/ Services Offered

14.5.4 The SNS View

14.6 Dassault Systemes

14.6.1 Company Overview

14.6.2 Financial

14.6.3 Products/ Services Offered

14.6.4 The SNS View

14.7 EnvisionTec, Inc.

14.7.1 Company Overview

14.7.2 Financial

14.7.3 Products/ Services Offered

14.7.4 The SNS View

14.8 EOS (Electro Optical Systems) GmbH

14.8.1 Company Overview

14.8.2 Financial

14.8.3 Products/ Services Offered

14.8.4 The SNS View

14.9 ExOne, GE Additive

14.9.1 Company Overview

14.9.2 Financial

14.9.3 Products/ Services Offered

14.9.4 The SNS View

14.10 HP Inc.

14.10.1 Company Overview

14.10.2 Financial

14.10.3 Products/ Services Offered

14.10.4 The SNS View

15. Competitive Landscape

15.1 Competitive Benchmarking

15.2 Market Share Analysis

15.3 Recent Developments

15.3.1 Industry News

15.3.2 Company News

15.3.3 Mergers & Acquisitions

16. Use Case and Best Practices

17. Conclusion

An accurate research report requires proper strategizing as well as implementation. There are multiple factors involved in the completion of good and accurate research report and selecting the best methodology to compete the research is the toughest part. Since the research reports we provide play a crucial role in any company’s decision-making process, therefore we at SNS Insider always believe that we should choose the best method which gives us results closer to reality. This allows us to reach at a stage wherein we can provide our clients best and accurate investment to output ratio.

Each report that we prepare takes a timeframe of 350-400 business hours for production. Starting from the selection of titles through a couple of in-depth brain storming session to the final QC process before uploading our titles on our website we dedicate around 350 working hours. The titles are selected based on their current market cap and the foreseen CAGR and growth.

The 5 steps process:

Step 1: Secondary Research:

Secondary Research or Desk Research is as the name suggests is a research process wherein, we collect data through the readily available information. In this process we use various paid and unpaid databases which our team has access to and gather data through the same. This includes examining of listed companies’ annual reports, Journals, SEC filling etc. Apart from this our team has access to various associations across the globe across different industries. Lastly, we have exchange relationships with various university as well as individual libraries.

Step 2: Primary Research

When we talk about primary research, it is a type of study in which the researchers collect relevant data samples directly, rather than relying on previously collected data. This type of research is focused on gaining content specific facts that can be sued to solve specific problems. Since the collected data is fresh and first hand therefore it makes the study more accurate and genuine.

We at SNS Insider have divided Primary Research into 2 parts.

Part 1 wherein we interview the KOLs of major players as well as the upcoming ones across various geographic regions. This allows us to have their view over the market scenario and acts as an important tool to come closer to the accurate market numbers. As many as 45 paid and unpaid primary interviews are taken from both the demand and supply side of the industry to make sure we land at an accurate judgement and analysis of the market.

This step involves the triangulation of data wherein our team analyses the interview transcripts, online survey responses and observation of on filed participants. The below mentioned chart should give a better understanding of the part 1 of the primary interview.

Part 2: In this part of primary research the data collected via secondary research and the part 1 of the primary research is validated with the interviews from individual consultants and subject matter experts.

Consultants are those set of people who have at least 12 years of experience and expertise within the industry whereas Subject Matter Experts are those with at least 15 years of experience behind their back within the same space. The data with the help of two main processes i.e., FGDs (Focused Group Discussions) and IDs (Individual Discussions). This gives us a 3rd party nonbiased primary view of the market scenario making it a more dependable one while collation of the data pointers.

Step 3: Data Bank Validation

Once all the information is collected via primary and secondary sources, we run that information for data validation. At our intelligence centre our research heads track a lot of information related to the market which includes the quarterly reports, the daily stock prices, and other relevant information. Our data bank server gets updated every fortnight and that is how the information which we collected using our primary and secondary information is revalidated in real time.

Step 4: QA/QC Process

After all the data collection and validation our team does a final level of quality check and quality assurance to get rid of any unwanted or undesired mistakes. This might include but not limited to getting rid of the any typos, duplication of numbers or missing of any important information. The people involved in this process include technical content writers, research heads and graphics people. Once this process is completed the title gets uploader on our platform for our clients to read it.

Step 5: Final QC/QA Process:

This is the last process and comes when the client has ordered the study. In this process a final QA/QC is done before the study is emailed to the client. Since we believe in giving our clients a good experience of our research studies, therefore, to make sure that we do not lack at our end in any way humanly possible we do a final round of quality check and then dispatch the study to the client.

The Arc Welding Torch Market was estimated at USD 2.10 billion in 2023 and is expected to reach USD 3.28 billion by 2032, with a growing CAGR of 5.09% over the forecast period 2024-2032.

The Micromachining Market Size was valued at USD 3 Billion in 2023 and is now anticipated to grow $9.19 Billion by 2031, with a CAGR of 5.26% by 2024-2031.

The Cartoning Machines Market size was estimated at USD 3.95 billion in 2023 and is expected to reach USD 5.83 billion By 2032 at a CAGR of 4.42% during the forecast period of 2024-2032.

Packaging Robots Market size was estimated at USD 6.02 billion in 2023 and is expected to reach USD 16.67 billion by 2032 at a CAGR of 11.98% from 2024-2032.

The Pneumatic Tube System Market size was valued at USD 2.43 Billion in 2023 and is expected to reach USD 4.44 Billion by 2032 and grow at a CAGR of 7.40% over the forecast period 2024-2032.

The Machine Safety Market Size was valued at USD 5.23 Billion in 2023 and is now anticipated to grow to USD 8.43 Billion by 2032, displaying a compound annual growth rate (CAGR) of 5.45% during the forecast Period 2024-2032.

Hi! Click one of our member below to chat on Phone